Enormous potential for sustainable production in manufacturing

EVVA uses large quantities of materials, particularly brass, nickel silver, cardboard, oils, emulsions, key blanks, etc. for the production of lock cylinders and keys. The potential for recycling and resource conservation is correspondingly diverse – and so are the positive impacts on the environment, people, and the economy. Sustainable material management has therefore been defined as an essential theme for EVVA in the stakeholder dialogue. EVVA regularly informs stakeholders about the company’s sustainability goals and milestones (e.g., via newsletters, magazines, events, etc.). The topic has:

- Ecological impacts: EVVA relies heavily on recycling to reuse materials as effectively as possible.

The brass for our security cylinders and keys comes from secondary materials: around a third from our own metal shavings, which are recycled through our suppliers, as well as from other remanufactured sources from our suppliers, such as copper cables. In addition to the ecological advantage, this also brings a qualitative advantage: the recycling processes make the materials more and more homogeneous in their chemical structure and thus easier to process by production machines. Recycling therefore increases the quality of the material.

Pure metal waste: Our own metal chips, which are generated during production, are recycled 100%. Other recyclable materials: EVVA successfully reached it's target to recycle 75% of all material (more under Recycling Materials). Thanks to improved production processes and lean management, we have been able to reduce waste in key production in recent years (more under Waste).

In its environmental policy, EVVA has defined clear guidelines for itself

> Use resources and energy sparingly

> Avoid emissions and waste as far as possible

> View waste as valuable resources

> Increase environmental awareness through information and dialogue with all employees

- Social/political impacts: Brass has a very low lead content, which simplifies machining (including production processes such as turning, drilling, or milling). “It is worth questioning a complete ban on lead in the door area for health reasons, as the proportions are minimal. But in the interest of sustainability, we are also researching alternative materials that still allow fast cycle times, high durability, and clean production,” explains Johann Notbauer, Group Manager for Market Innovation and Technology at EVVA.

- Economic impacts: Due to the war in Ukraine, the pandemic, and global shortages, the cost of materials has increased significantly. For example, the price of copper (an important processing material for brass cylinders) has more than doubled. Our company was one of the last in the industry to introduce material surcharge increases due to the sharp increase in purchase costs, which were also comparatively moderate. This has been appreciated by many partners and customers. EVVA closely analyses market price developments to take advantage of favourable purchase times.

Input-Output Analyses

The measured data given in the following analyses have been published in EVVA’s environmental reports and in the energy audit. They have been externally verified and confirmed by authorities (e.g., Environmental Magistrate, Waste Magistrate, Trade Authority, representatives of the Chamber of Labour and Chamber of Commerce) and sustainability consultants.

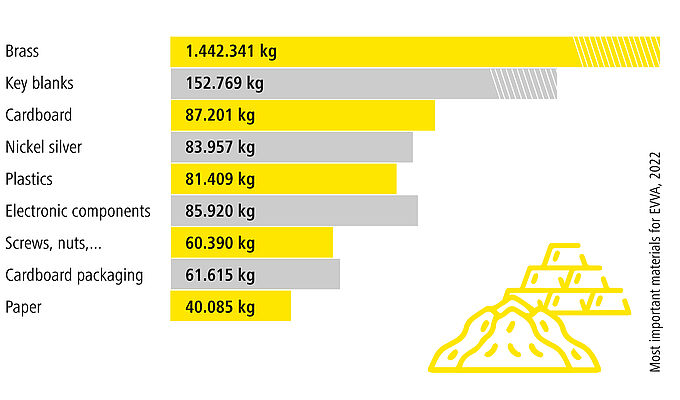

The input-output analyses (2023 is available for the next update at the end of 2024) document the most important materials/resources that EVVA requires for the production of access systems. Of these, wood, cardboard, packaging and more are renewable materials. We also include brass and nickel silver, as all metal chips generated during processing are recycled in full (see Recycling Materials).

Input/output analyses (in German): 2022

The most important materials for EVVA

Material usage

Brass is our main material for production. The brass content of the total metal demand is about 80%. The demand for brass at the headquarters has increased by 10% from 2015 to 2019 to 1.6 million kg. In 2020, demand decreased due to the economic pandemic restrictions. This trend continued in 2021 and 2022 (Requirements for approx. 1.4 million kg each) - not due to the pandemic -, but due to the increasing demand for electronic EVVA access control solutions. The share of our electronic solutions in total business also increased in 2022, resulting in a reduction in brass demand. The share of electronic components has increased by 25% from 77,405 kg (2021) to around 85.920 kg (2022) .

EVVA was able to further reduce waste from 2021 to 2022 (more about that in the section Waste in the input-output-analysis above). The demand for oil decreased further due to the increased use of clean production machines: from 6.8 tons in 2019 to 5.7 tons in 2027 and 4.3 tons in 2022.

Overview of measures

To reduce our material usage or use it more efficiently, we rely on various strategies and measures. Follow the links for more interesting details:

- Clean Production which greatly reduces the demand for oils, emulsions, and water

- High recycling rates for materials and water

- Innovations such as Low Power Design and modular cylinders

- Digitalisation projects

- Waste reduction measures

- Own photovoltaic system to reduce demand and transport of fossil fuels

You find current targets related to recycling & resources under:

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?