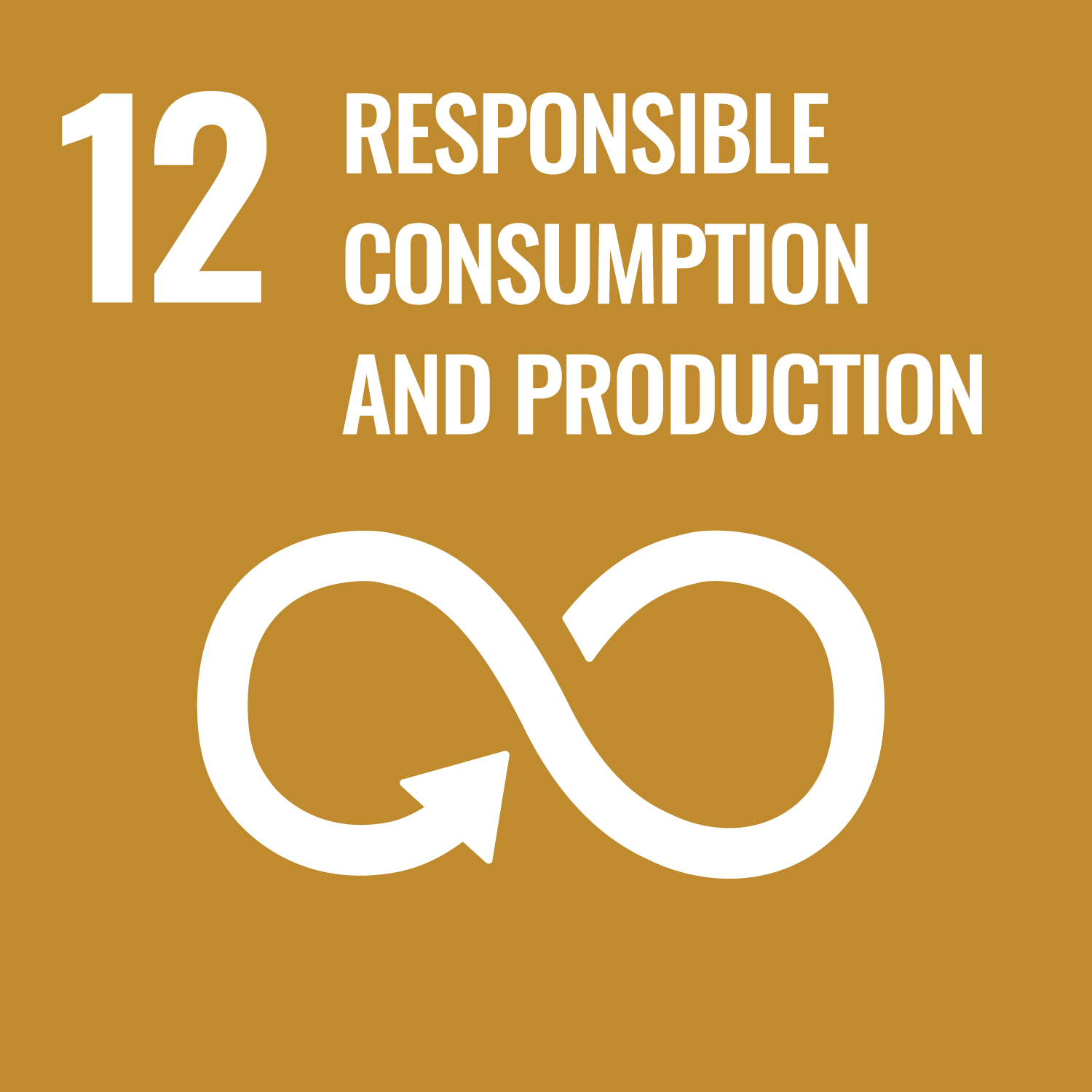

Waste as a raw material

EVVA sees waste as a raw material that must be used as sparingly as possible. Waste prevention starts with the inflow and use of resources. A topic that EVVA has identified as essential at the headquarters (which organises virtually all of the Group’s purchasing). Our concepts and “R” principles (Recycling, Reduce, Reuse, etc.) are described under Circular economy overview.

As of 2024:

- 68.2% of our materials become finished EVVA products,

- 28.6% is recyclable waste (chips, solid waste, etc.). EVVA recycles the metal shavings into

100%! That is why we refer to "recyclables', not to "waste', - 2.14% is non-hazardous waste such as plastics or wood

- and 1.06% is hazardous waste such as oil, electronic scrap, electroplating waste or batteries

Paper, brochures

EVVA will further reduce paper consumption - see target description under Circular economy at a glance.

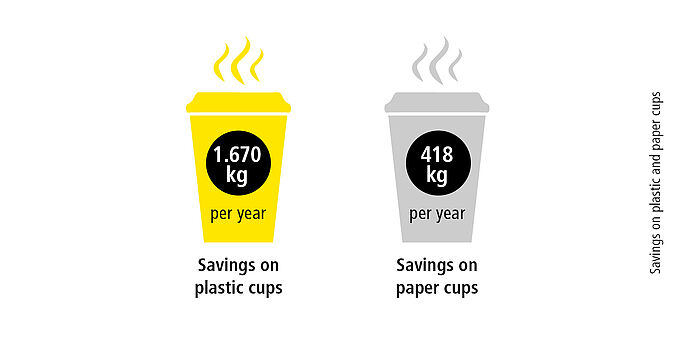

Ban plastic/paper cups

EVVA has banned all plastic mugs from the coffee machines in the headquarters and initially replaced them with paper mugs. Here, too, EVVA continued: Employees were asked to use their own coffee cups on the intranet and via adhesive directly on the vending machine instead of using paper cups. To promote this promotion, all employees received an EVVA-branded copy as a gift that they could personalise themselves. The campaign was a great success. With around 15,000 portions of coffee consumed every month, the savings are impressive:

Environmentally friendly thermal paper

EVVA has switched its cash register paper for goods issue and internal logistics to blue thermal paper (Blue4est). It has been awarded several environmental awards, is produced without bisphenol A, can be disposed of with waste paper (the previous white only with residual waste), does not fade and is also cheaper to purchase.

Key blanks

Key blanks

The need for key blanks (the original shape of the key before machining) fell from 88,947 kg in 2023 to 78,437 kg in

2024. Lean management tools (value stream analyses, Kanban, etc.) that target waste have made a contribution.

Hazardous waste

such as oil or electronic waste. These materials are required for electroplating and for production. They are disposed of professionally by specialist companies in accordance with legal requirements. No leakage of harmful substances has occurred. Information for headquarters:

- The amount of waste oil has decreased from 757 kg (2023) to 649 kg (2024). This is due to our ongoing transition to oil-free clean production machines

- The amount of liquors/lye mixtures has also decreased from 8.3 t (2023) to 6.9 t (2024) due to more efficient electroplating processes

Without perchloroethylene: The cleaning system at the headquarters, which EVVA purchased in 2022 (photo on the right), cleans all brass parts - which are not yet manufactured in dry machining, i.e. not in Clean Production - of oil and emulsions. Its special feature: It does not require perchlorine, only modified alcohol. This means that it not only washes in a much more environmentally friendly way, but also more thoroughly, as this alcohol can absorb water. A big plus for security, environment and quality

Without perchloroethylene: The cleaning system at the headquarters, which EVVA purchased in 2022 (photo on the right), cleans all brass parts - which are not yet manufactured in dry machining, i.e. not in Clean Production - of oil and emulsions. Its special feature: It does not require perchlorine, only modified alcohol. This means that it not only washes in a much more environmentally friendly way, but also more thoroughly, as this alcohol can absorb water. A big plus for security, environment and quality

- Electronic scrap has decreased (currently 2.3 t) because several old machines and control systems have been scrapped in recent years as part of the new expansion at the headquarters

- Due to the increased demand and production of electronic and mechatronic safety systems, battery demand has increased in recent years (from a few kg in 2010 to

662.5 kg in 2024) and consequently battery waste. The batteries are not disposed of annually, but collected for up to 2 years

New electroplating processes

EVVA has partially switched its electroplating processes (for the surface treatment of our mechanical security products) at headquarters from powder to liquid. This simplifies the automated feeding of substances and thus an efficient and quantity-reduced supply.

Lifetime

Products and components such as batteries with a longer useful life also generate less waste and sets an example against the throwaway society. For more information, see Quality and Permanent Innovation.

Recycling, recyclable waste

Read more about our recycling under Recycling Materials and Recycling Water/Wastewater.

Fulfilment date: 2026 (Target postponed from 2024 to 2026)

How: In the coming years, EVVA will promote paperless production and digital order processing, which will reduce paper consumption.

- An example from internal order processing: Instead of the previous 3 delivery notes for orders, only one form will now be necessary. The data flow will be provided digitally for shipping.

- Another example from order processing with partners: the new digital EVVA order platform for trade partners will further reduce paper usage.

Positive impacts: In 2019, the paper requirement at the EVVA headquarters was 43 tons per year. The planned reduction to 30 tons represents a saving of around 30% per year.

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?