Management approach – our why

As a manufacturer, our goal is to use resources sparingly and reuse them as well as possible. EVVA’s environmental policy (available at https://www.evva.com/int-en/aboutus/company/#tab4 ) emphasises the sustainable use of resources.

Even though EVVA’s circular concepts are diverse, as described below: The path to a more circular economy is challenging. The materials that EVVA uses as a production company do not fully return to the cycle. EVVA has therefore assessed resource inflows, including resource use, as a material negative impact. In addition, as a production company, we have a higher resource requirement than companies in other industries. In addition to our own business activities, this mainly affects our upstream value chain.

Our approaches to an active circular economy (ESRS E5-1)

EVVA requires resources such as brass, nickel silver, cardboard, paper, etc. to manufacture security cylinders and keys. The potential for conserving resources concerns inflow/purchasing, the use of resources in production and product planning. The vast majority, 95%, of raw materials are purchased via the Vienna headquarters for all EVVA branches. As the EVVA Group’s inflow of resources is therefore practically only driven via one location, the data specified here refers to the EVVA headquarters. The remaining 5% are marginal in the overall view.

Circular economy concepts are planned, implemented and monitored by EVVA units such as Logistics & Purchasing, Production or Research & Development. The upstream value chain is essential for a circular economy at EVVA. Therefore, we are also in ongoing dialogue with the main suppliers in order to exploit the opportunities of recycled materials in the inflow of resources.

Our actions to use resources more sustainably (ESRS E5-2)

EVVA has implemented several circular priorities in the year under review and in recent years, as reflected in the following overview of our “R” concepts and measures.

Recycle

EVVA focuses heavily on recycling in order to recycle the materials used as well as possible.

- Brass and nickel silver are by far the most important materials for our production. EVVA has been reusing 100% of the metal shavings produced during the processing of our access solutions – and has been doing so for many decades. They are melted in at the supplier and return to the production process in their entirety

- EVVA purchases a high proportion of recycled materials in the upstream value chain. Already 90% of our brass comes from secondary materials. More details can be found in the target description at the bottom and under Recycling materials

- Our product packaging for sale has been made from 100% environmentally friendly, recyclable cardboard since 2017. For more information, see Recycling materials

- A vacuum evaporator treats the wastewater from the electroplating process 100% and returns it to the production cycle. For more information, see Water and wastewater recycling

- Another reason for our high recycling rate is that EVVA is increasingly using “machining technology” for complex product parts, which separates excess material in the form of chips and thus increases recycling

Reduce

Even better than recycling, it is to reduce the need for resources. EVVA can demonstrate many years of successful measures.

- EVVA’s Clean Production protects the environment and resources because it operates dry, i.e. it produces without oil, emulsions and water. More information under Clean Production

- Energy: Our need for fossil energy is decreasing continuously, among other things through energy saving measures, the expansion of our own photovoltaic systems and environmentally conscious energy procurement. EVVA already obtains 100% of its purchased electricity from hydropower at the headquarters. More information under Energy & Emissions overview, Photovoltaics and Power management

- Paper. By switching to digital processes, EVVA has been able to save several tonnes of paper at the headquarters in recent years. More details can be found in the target description at the bottom and under Recycling materials

Reuse/Repair

EVVA products have a very high durability, which has a positive effect on the long-term use of resources by end users. EVVA cylinders can be removed and reused for similar door situations, e.g. when moving house. EVVA uses reusable transport packaging in its own business activities, but also in the downstream value chain.

- According to the EPD (Environmental Product Declaration, available under Certifications ) – which are voluntary environmental declarations for individual building products to indicate the life cycle assessment of buildings – the service life of a mechanical locking cylinder is 30 years. So they are anything but disposable products with only a short lifespan. EVVA continues to receive many reorders of systems that have been in use for half a century and longer

- Repairs are therefore rare for mechanical products. EVVA still offers a repair service; electronic components, for example, are checked at EVVA’s ELREZ (electronics repair centre)

- Internal packaging/reusable pallets. In recent years, EVVA has increased its share of reusable internal packaging to around 85%. For more information, see Recycling materials

Rethink

Product development and design can positively influence the use of resources. In addition to economic requirements (how must the product be developed so that it also generates profit?) and social requirements (how can safe use be guaranteed?), EVVA also considers ecological impacts in its product design.

- Sustainability is anchored in EVVA’s R&D specifications and product lifecycle management. New products are tested accordingly over their life cycle (e.g. recycling potential; minimum energy consumption over the average duration of use; connected devices that enable maintenance via radio, etc.)

- Low power design. EVVA uses advanced semiconductor technologies for electronic access solutions, which are also used in smartphones and wearables. This means that the batteries are ready for use much longer. For more information, see Permanent Innovation

- The modular design of locking cylinders can reduce waste. For more information, see Permanent Innovation

- Brass has a very low lead content, which leads to a very environmentally friendly clean production process for machining (i.e. manufacturing processes such as to turn, drill or to mill). "A complete ban on lead in the door area must be questioned from health aspects, as the proportions and so-called leadlessness are minimal. In the interests of sustainability, however, we are also researching alternative materials that continue to enable a fast cycle time, high durability and clean production," explains Johann Notbauer, Executive Vice President of Market Innovation and Technology at EVVA.

Refuse

Another way to conserve resources is to stop producing a product and instead offer its function in a different form. The sharing economy is an example of this.

- EVVA offers key credits for the Xesar and AirKey electronic access systems. End users can share and revoke access to their properties via their smartphone. Access authorisation is no longer via physical keys or cards, but via the smartphone. For a new access authorisation, e.g. for a cleaning service or for assisted living, no new key is produced in this business model, but instead a virtual KeyCredit is used to authorise the third-party smartphone for access

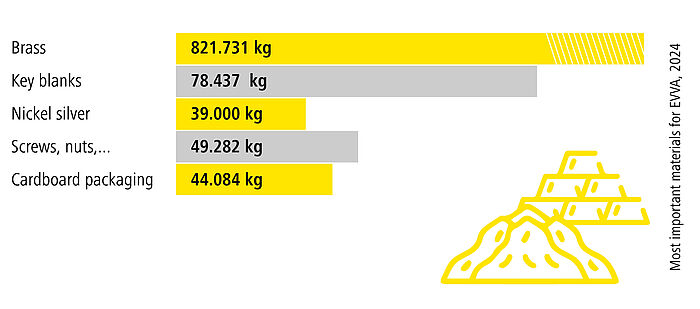

Resource inflows (ESRS E5-4)

| Input | 2024 | 2023 |

|---|---|---|

| Brass | 821,731 kg | 800,107 kg |

| Key blanks | 78,437 kg | 88,947 kg |

| Nickel silver | 39,000 kg | 16,553 kg |

| Cardboard packaging | 44,084 kg | 43,145 kg |

| Plastics | 4,753 kg | 6,951 kg |

| Screws, nuts … | 49,282 kg | 66,864 kg |

| Printed circuit boards | 1,818 kg | 2,701 kg |

| Paper | 4372 kg | 4,557 kg |

| steel | 5517 kg | 12,987 kg |

| Zinc pressure parts | 1,543 kg | 5,206 kg |

| Brochures | 1,515 kg | 1,565 kg |

| Total | 1,052,052 kg | 1,049,583 kg |

| Water | 4,191 m³ | 4,050 m³ |

| Oil | 9,332 l | 14,935 l |

For information on electricity/gas, see Energy & Emissions Overview

As the table of resource inflows shows, brass is by far the most important resource for EVVA and is therefore prioritised in our circular economy. It is the main material for locking cylinders and keys.

- In 2024, EVVA expanded its warehouse and procured more brass and nickel silver to be well prepared for unexpected supply fluctuations

- In 2024, fewer quantities of oil (due to the higher clean production share), key blanks (due to more recycling and more efficient lean management), screws/nuts and zinc pressure parts (increased share of electronic access solutions in the product mix), paper (increasing digitalisation), steel (fewer own machines built that require steel) were required

All of the following goals continue to drive EVVA’s circular economy forward. In this way, we want to increase the circular material utilisation rate and further minimise the consumption of primary raw materials. EVVA’s measures to become independent of fossil energy sources are described under Energy & Emissions Overview.

By when:

Target year: 2028. Base year: 2025

Scope and positive effects:

Brass is the most important metal for EVVA production and accounts for approximately 80% of total metal requirements. 100% of the brass shavings produced during EVVA's manufacturing process are already melted down and recycled. This accounts for approximately one third of the current recycling rate of 90%. The other two thirds come from the scrap trade of our suppliers. Together with them, we are now trying to increase this figure to an even higher 94%. This would further significantly reduce the demand for primary raw materials.

Method, validation:

Ongoing cooperation with suppliers to promote recycling; confirmation of the recycling rate by brass suppliers.

Value chain/location:

Upstream value chain, EVVA headquarters in Vienna

Target pursuit:

‘Logistics & Purchasing’ department

By when:

Target year: 2030. Base year: 2024

Scope and positive effects:

Nickel silver is the second most important metal for EVVA production and accounts for approximately 12% of total metal requirements. Currently, 75% of the nickel silver purchased comes from recycled materials. In consultation with our main supplier, we want to increase this figure to 90% in order to keep the proportion of primary materials to a minimum.

Method, validation:

Ongoing cooperation with suppliers to promote recycling; confirmation of the recycled content by nickel silver suppliers.

Value chain/location:

Upstream value chain, EVVA headquarters in Vienna

Target tracking:

‘Logistics & Purchasing’ department

By when:

Target year: 2027. Base year: 2019

Scope and positive effects:

The planned reduction from 8.3 tonnes (2019) to 3.4 tonnes (by 2027) will result in savings of around 60%. EVVA is promoting paperless production and digital order processing. Copy paper in thicknesses of 3.82 g and 4.28 g accounts for the majority of our paper consumption. Our demand for this has fallen from 4.6 tonnes in 2023 to 4.4 tonnes in 2024 thanks to digitalisation and consumption reduction. This means that 80% of the target has been achieved so far.

Method/validation:

Status of consumption values from the internal ERP (Enterprise Resource Planning) system.

Location/value chain:

EVVA headquarters in Vienna

Target tracking:

‘Mechatronics Production’ division

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?