Management approach - our why

EVVA has assessed CO2 emissions and energy consumption as having a significant negative impact. As an industrial company that supplies numerous high-quality access systems to the world, EVVA has a corresponding energy requirement and emits CO2 itself and via the value chain. Our climate protection measures, such as reducing overall energy consumption and driving greenhouse gas neutrality, are therefore among the most important sustainable pillars of our company. They are discussed and evaluated in the top management strategy meetings and in the Sustainability Board. Climate protection and energy efficiency

- Environmental impacts: A policy on energy use that focuses on decarbonisation, renewable sources and efficient use counteracts negative impacts on the environment and reduces CO2 emissions. A task that Europe and EVVA have committed themselves to

- Economic impact: Energy costs have increased in recent years. Reducing energy consumption has a positive effect on purchasing costs and competitiveness. Therefore, in addition to the major savings targets described below, EVVA is also focusing on smaller, but not less important activities, such as maintenance work on windows and exterior doors (sealing windows, replacing seals), raising employee awareness so as not to waste energy unnecessarily (e.g. do not forget to turn off heating overnight) or switching off illuminated outdoor advertising

- Social/political impact: If companies and households are able to optimise their energy needs, this will support national and EU-wide efforts to implement the Green Deal as hoped and become more independent in energy procurement

Our approaches to climate change mitigation and adaptation (ESRS E1-2)

EVVA will first reduce its greenhouse gas emissions further at the headquarters, which is the EVVA Group’s main production site. At the same time, the increased electricity demand (successively replacing gas/petrol/diesel) will be kept within limits by energy-saving measures and our own renewable energy.

EVVA’s environmental policy can be accessed at any time at https://www.EVVA.com/at-de/ueber-uns/unternehmen/#tab4. It aims to minimise the negative impact on people and the environment and to use resources such as energy and materials efficiently. This applies not only to EVVA itself, but to our entire value chain. EVVA is making its contribution to consistently implementing the Green Deal - even before the EU’s 2050 target. Compensation certificates have not yet been used; the transition is primarily intended to be achieved on its own. EVVA’s strategic focus - approved and under the responsibility of the management - is on the following aspects, which have a particularly large leverage in terms of climate protection and mitigation of global warming:

- Decarbonisation: Replacing fossil fuels with renewable energy is the most important step. EVVA has been reducing its greenhouse gas emissions for many years by pursuing the following goals:

> align the electricity tariff with renewable energies such as hydropower,

> minimise the proportion of natural gas,

> convert the fleet from petrol/diesel to electric vehicles.

More about our emissions including our decarbonisation targets under CO2 neutrality

Own renewable energy: EVVA not only procures renewable energy (electricity tariff at headquarters: 100% hydropower), but also installs its own photovoltaic systems. We currently have our own PV systems in operation at the headquarters in Vienna, as well as in Villorba (Italy) and Hengelo (Netherlands). More are planned. More information under Photovoltaics

Own renewable energy: EVVA not only procures renewable energy (electricity tariff at headquarters: 100% hydropower), but also installs its own photovoltaic systems. We currently have our own PV systems in operation at the headquarters in Vienna, as well as in Villorba (Italy) and Hengelo (Netherlands). More are planned. More information under Photovoltaics

- Efficient energy management: EVVA is establishing a new digital energy management system to make electricity and gas consumption clearer and faster. The technical installations are connected with consumption sensors to measure individual energy requirements. Read more about our energy-saving measures under Energy management

- Climate change adaptation: EVVA has carried out a climate risk analysis for six locations in order to determine the impacts of climate change. In addition, several roof structures at the headquarters will be renovated and new thermal insulation installed

- Stakeholder dialogues: EVVA is in ongoing dialogue with the main suppliers in order to procure the main material brass mainly from recycled materials instead of primary materials. This reduces our Scope 3. We do our part to ensure that 100% of our metal shavings generated during production are returned to the material cycle.

Read more under Circular economy at a glance

Energy consumption and energy mix (ESRS E1-5)

Total energy consumption of the three EVVA Power Plants:

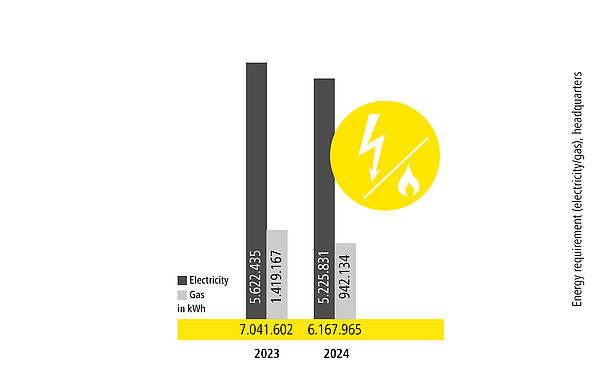

| 2024 | 2023 | |

|---|---|---|

| Headquarters Vienna, main production site | Current: 5,225,831 kWh Gas: 942,134 kWh Total: 6.167,965 kWh (6,167.97 MWh; 6.1 GWh) | Current: 5,622,435 kWh Gas: 1,419,167 kWh Total: 7,041.602 kWh (7,041.6 MWh; 7 GWh) |

| Krefeld | Current: 140,824 kWh Gas: 139,278 kWh Total: 280,102 kWh | |

| Tišnov | Current: 124,700 kWh Gas: 1,301 kWh Total: 126,001 kWh | |

| EVVA Power Plants in total | Current: 5,491,355 kWh Gas: 1,082,713 kWh Total: 6,574,068 kWh |

The energy consumption of the two other power plants in Krefeld and Tišnov together accounts for only about 6% of the consumption at the headquarters. Other EVVA locations are mainly administrative and have even lower energy consumption.

Total energy requirements of EVVA headquarters incl. main production site, 2023 and 2024. The table does not include electricity generation from our own photovoltaic system.

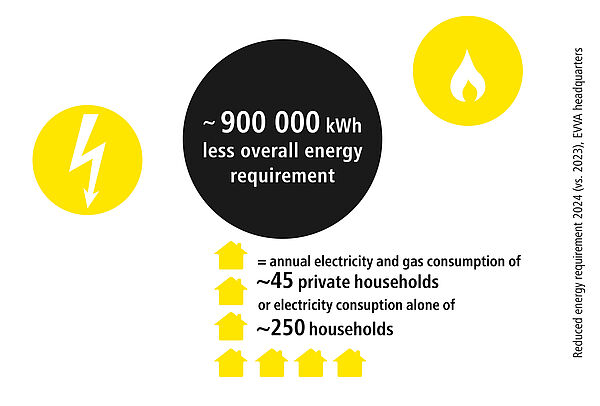

Reduced energy consumption!

- The total energy requirement (electricity and gas) at the headquarters amounts to 6,167,965 kWh in 2024. This results in savings of around 900,000 kWh compared to 2023! As much as around 250 households consume electricity per year (assumed: 3,500 kWh) or 45 households consume electricity plus gas (assumed: 20,000 kWh). Most of the electricity we need for our manufacturing processes: for machines/production (approx. 50%), compressed air/compressors (30%), heating (15%), workstations/PCs and others (5%). Gas is still used for heating

- Electricity demand decreased by approx. 400,000 kWh from 2023 to

2024. Reasons for the savings:

> Newly installed Smart Optimizer that controls the compressors on demand and thus more energy efficiently (no more standby energy losses). Savings: approx. 300,000 kWh

> New more energy-efficient air conditioning system (Bluebox) for production, which significantly reduced electricity consumption in summer (savings: approx. 70,000 kWh)

> New purchase of energy-saving compressors (savings: approx. 30,000 kWh)

- Gas demand decreased by approx. 500,000 kWh from 2023 to

2024. Reasons for the savings:

> Start of conversion to heat recovery via the newly purchased compressors. This drastically reduced gas consumption (savings: approx. 200,000 kWh)

> Warmer winter 2024 and more energy-efficient heating (savings: approx. 200,000 kWh)

> Various renewals for heating systems (thermostat replacement, etc.). Savings: approx. 100,000 kWh

- In 2022, the total energy requirement was still 7,336,018.93 kWh, of which around 1,710,000 kWh was gas and around 5,625,000 kWh was electricity. EVVA was therefore able to significantly reduce its energy requirements in just a few years

Our energy measurement data is published in energy audits (based on the Federal Energy Efficiency Act) and checked and confirmed by external energy auditors.

Total consumption by energy source, headquarters:

| 2024 | 2023 | |

|---|---|---|

Renewable sources | 5,225,831 kWh | 5,622,435 kWh |

| Fossil sources (= gas) | 942,134 kWh | 1,419,167 kWh |

| Nuclear energy | 0 | 0 |

This means that in 2024, over 80% of our energy came from renewable sources (= total purchased electricity from hydropower). The solar energy generated from our own PV systems is not included here. Thanks to them, however, EVVA has to purchase less electricity, more about photovoltaics.

Further measures and targets for energy & emissions under these topics:

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?