Management approach – our why

As an industrial company that produces high-quality access systems, EVVA has a corresponding energy requirement. EVVA itself emits greenhouse gases (GHG, Scope 1) via heating and its vehicle fleet. Our emissions are steadily decreasing due to the switch from gas to green electricity and to electric vehicles. For Scope 2, i.e. purchased electricity, the headquarters is already on net zero. The largest GHG factor is Scope 3, i.e. emissions that occur in the upstream and downstream value chain. Brass is our most important production material and is required for the production of our security cylinders and keys in larger quantities. Brass production at our suppliers causes correspondingly high GHG emissions.

For this reason, EVVA has defined GHG emissions as a material negative impact in our own business activities and also in the value chain. Our emissions relate almost exclusively to CO2. Only refrigerants for air conditioning systems, which only need to be refilled every few years, contain very small amounts of fluorinated gases, which are taken into account in Scope 1. Our GHG targets and measures contribute to achieving the EU’s Green Deal.

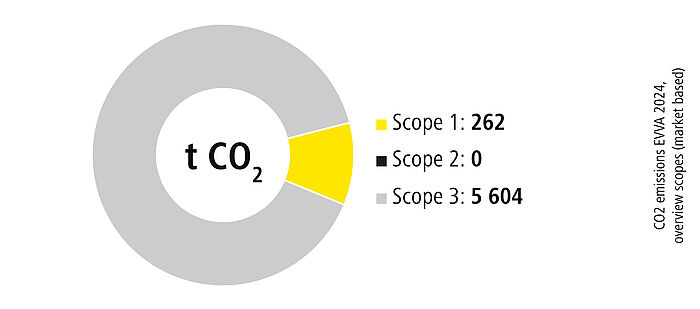

Our CO2 footprint. Gross GHG emissions (ESRS E1-6)

The following table includes all GHG emissions from the EVVA headquarters (main production site) in 2024 and 2023. Data for the other two, much smaller power plants in Krefeld and Tišnov are planned from the reporting year 2025. The other EVVA branches are mainly sales locations and have only very low energy consumption and GHG emissions.

Notes on the table:

-

Scope 1 = own emissions (heating, fleet); Scope 2 = emissions of purchased electricity; Scope 3 = indirect emissions from the upstream and downstream value chain, e.g. from suppliers

-

“Location-Based” means: determined average emission factor of the regional electricity grid. It represents the energy mix of the regional electricity grid. “Market-related” means: emissions based on a company’s contractual electricity tariff; taking into account how the electricity was produced. The market-based calculation therefore reflects a company’s individual efforts to procure electricity in a more climate-friendly way!

-

The basis for our scope calculations is the GHG protocol, the ecoinvent database 3.10 and 3.11 as well as information from suppliers. Information on estimated values is given in the ESRS index under item "ESRS 2, BP-2

Information in tonnes of CO2 equivalent (CO2 e) for all three scopes and total

| EVVA headquarter | 2024 | 2023 |

|---|---|---|

| Scope 1 | ||

| Gross GHG emissions Scope 1 (t CO2 e) | 262.3 t | 354.9 t |

| % from regulated emissions trading schemes | 0% | 0% |

| Scope 2 | ||

| Market-related gross GHG emissions Scope 2 (t CO2 e), EVVA purchases 100% green electricity | 0 t | 0 t |

| Location-related gross GHG emissions Scope 2 (t CO2 e), according to the Federal Environmental Office | 1,201.9 t | 1,293.2 t |

| Scope 3 | ||

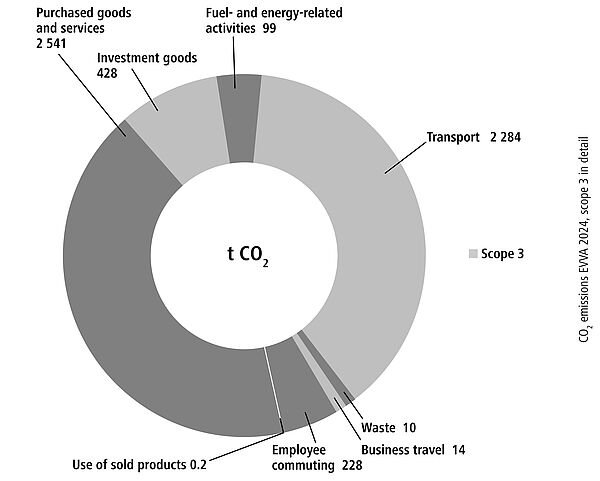

| Total indirect gross GHG emissions Scope 3 (t CO2 e). Divided according to GHG protocol into: | 5,604.3 t | 6,461.7 t |

| 1 Purchased goods and services | 2,541.3 | 2,860.5 |

| 2 Capital goods | 428.2 | 849.4 |

| 3 activities related to fuels and energy (not included in Scope 1 or 2) | 98.5 | 123.8 |

| 4 Upstream transport and distribution | 2,284 | 2,338.1 |

| 5 Waste generation in operations | 10.25 | 10.8 |

| 6 Business trips | 14.4 | 30.8 |

| 7 Commuting employees | 227.5 | 248.1 |

| 8 Upstream leased assets | - | - |

| 9 Downstream transport | - | - |

| 10 Processing of sold products | - | - |

| 11 Use of sold products | 0.2 | 0.2 |

| 12 Treatment of products at the end of their service life | - | - |

| 13 Downstream leased assets | - | - |

| 14 Deductibles | - | - |

| 15 Investments | - | - |

| Total GHG emissions | ||

| total market-related (t CO2 e) | 5,866.6 t | 6,816.6 t |

| total site-related (t CO2 e) | 7,068.5 t | 8,109.8 t |

Improvements in the EVVA CO2 footprint

Our total GHG emissions have decreased by 950 tonnes last year. This means that the corporate carbon footprint (CCP) of the headquarters has fallen by 14% from 2023 to 2024! The reasons are as follows:

For Scope 1:

- Our Scope 1 emissions are 92.6 tonnes lower in 2024 compared to 2023. The reason for this was, on the one hand, the lower gas demand due to our heat recovery via the new compressors since November 2024 and, on the other hand, the warmer winters. Scope 1 covers the company’s own direct emissions, i.e. each company can make the greatest impact here to reduce them

For Scope 2:

- EVVA Headquarters purchases 100% green electricity from hydropower (since 1 January 2022), which means it has already reached Net Zero in Scope 2!

For Scope 3:

- “Purchased goods and services” is a central Scope 3 value for EVVA, as this includes the emissions that arise during the production of brass, for example. Brass is the most important material for the manufacture of our security products. These emissions decreased by 319 tonnes, partly due to lower purchasing volumes for plates, steel and zinc printing parts. But also because the recycled content of the brass and nickel silver we purchase is increasing

- In 2024, fewer flights were made at EVVA (halved from 259 flights in 2023 to 121 flights in 2024), which is why the GHG value for “business trips” fell accordingly

- The reduction in “commuting employees” is a consequence of the gradual switch from diesel/petrol vehicles to electric cars at EVVA

- “Downstream transport”: According to the GHG protocol, transports from EVVA to customers also count as “upstream” if external logistics partners are commissioned for this purpose. Therefore, these deliveries are listed under "4: Upstream transport and distribution" and not under "9: Downstream transport"

- “Processing of sold products”: EVVA already delivers finished products

- “Use of sold products”: This factor is practically unimportant at EVVA, because our mechanical access solutions do not consume any energy when in use and our electronic solutions also have extremely low emissions via batteries. This means that EVVA products cause virtually no CO2 emissions for customers and partners in daily use

- “Treatment of products at end of service life”. EVVA products have a very long service life – e.g. 30 years for mechanical cylinders according to the EPDs (Environmental Product Declarations) - and are often used across generations. We therefore do not know how many EVVA products are disposed of in order to calculate a recycling rate and GHG

Our targets and actions to further reduce emissions (ESRS E1-3 and E1-4)

EVVA has implemented or planned the following objectives and measures. Additional information on transition plans can be found in the ESRS index under E1-1. The GHG targets initially relate to the EVVA headquarters with the main production site. Targets for further EVVA locations are planned.

Notes on the table:

-

The methodology and validation of objectives includes: own energy management system with new calculation of the GHG accounting, own measurements and information from external service providers (energy supplier, compressor manufacturer). The goals are evaluated by the EVVA “Global Industrial Engineering” or “Logistics & Purchasing” units

-

According to science-based targets, the net-zero target is achieved when: 1) For Scope 1, at least 95% of emissions are neutralised by 2050, 2) for Scope 2, electricity will come from 100% renewable energy sources by 2030; 3) for Scope 3 at least 90% of emissions neutralised by 2050

-

The original goal of being Scope 1 CO2 neutral by 2030 is currently not achievable. Currently, electricity is 2-3 times more expensive than gas, making it economically difficult to quickly switch to electricity. EVVA has therefore extended the target to 2035

EVVA target | Planned CO2 reduction | Starting Year | Target Year | Progress |

|---|---|---|---|---|

| Long-term target | ||||

CO2 neutral for Scope 1 | Net Zero

| 2020: | 2035 | Approx. 40% reached. |

| Near-term targets | ||||

| Use waste heat from new compressors. They are integrated in the heating return | 246 t | 2024 | 2027 | approx. 70% achieved |

| Renovation of roof structures including thermal insulation | 12 t | 2025 | 2027 | 0% |

| EVVA target Scope 2 | Planned CO2 reduction | Starting Year | Target Year | Progress |

|---|---|---|---|---|

Purchased electricity from 100% renewable energy sources | Net Zero

| 2020: | 2030 | 100%. |

| EVVA target Scope 3 | Planned CO2 reduction | Starting Year | Target Year | Progress |

|---|---|---|---|---|

Reduce Scope 3 emissions by 35% | 2,262 t | 2023: | 2030 | 40% achieved. |

The implementations in detail:

- Integration of the compressor waste heat into the heating return

Since 2024, the waste heat from the existing and newly purchased compressors (which generate the compressed air for production) has helped to gradually replace the gas for heating. For this purpose, heat exchangers are installed in the compressors, which direct the waste heat into the heating return.

Another potential approach is to also use waste heat from machines. The heat recovery system currently consists of a flap in the exhaust air duct. In winter, the machine heat is conducted into the hall, thus saving heating gas; in summer, it is dissipated, thus saving energy for cooling and air-conditioning systems. EVVA is first evaluating the experiences with the waste heat of the compressors before further plans for machine waste heat are implemented.

Approx. 70% of the target has already been achieved. In the first stage, the main heating room (covering most of the total heating demand) was replaced. Currently, 2 out of 4 active compressors are integrated in the heating return, a third will soon be integrated.

Positive effects:

The calculated energy saving from heat recovery is 1.210,000 kWh, i.e. 1.21 GWh. The CO2 saving is 246 tonnes. The waste heat from the compressors would therefore contribute significantly to our net zero target for Scope 1.

- Renovation of several roof structures including thermal insulation

Soon, several roofs above the headquarters will be completely renovated and re-insulated. This will reduce the heat demand.

Positive effects:

The savings are estimated at 50,000 kWh or 12 t CO2. However, the focus of the project is on improving the building structure.

Conversion to electric fleet

Conversion to electric fleet

EVVA is pushing for the switch to electric vehicles where it makes sense. Although an electric car is not yet ideal for all purposes, such as for long-distance sales teams, the ranges are getting better and better. As more electric vehicles and fewer conventional cars are to be produced in the future, the trend is clearly moving towards electric mobility.

At the beginning of 2025, the share of electric vehicles in the fleet was 26% (11 pure electric cars, 3 hybrid/petrol, 3 petrol, 24 diesel). At the beginning of 2024 at 20% (8 pure electric cars), in 2023 at 10%.

Positive effects:

The CO2 emissions of the headquarters fleet will continue to decline in the coming years and reduce the Scope 1 share. In 2020, the headquarters’ fleet still emitted 171 t of CO2, mostly from diesel vehicles. Only 73.9 t in 2024 due to the ongoing switch to electric cars.

- Share of regional suppliers already increased to 97%

The higher the share of our regional suppliers, the shorter the transport routes and lower the emissions from transport. For details, see Proportion of regional suppliers.

Positive effects:

After calculating the EVVA “Logistics & Purchasing” unit, approx. 1 million euros of EVVA’s purchasing revenue in the region, thereby helping to secure or expand jobs for suppliers. The shorter transport routes (less air freight from Asia) saved over 100 tonnes of CO2 (2023: 168 t GHG based on medium/long flight distance; only 41 t in 2024). The transports to EVVA (e.g. from the brass supplier to EVVA headquarters) have a larger scope of delivery per trip, but since there are only a few trips, they also cause less GHG emissions. Unlike EVVA’s transports (e.g. from headquarters to subsidiaries or trading partners): Although delivery volumes are lower here, the more frequent single trips to different countries mean higher GHG emissions.

- Continue to increase the recycled content of purchased materials

Among other things, we want to reduce the Scope 3 share through intensive exchange with suppliers. A major lever here is the procurement of secondary instead of primary materials. Read more about our respective goals under Circular Economy overview

- 50% travel

allowance from EVVA for employees at headquarters. These subsidies only apply to public transport, not to cars. This means they have a steering influence and reduce the environmental impact of individual transport.

- Clean production

EVVA’s much lower oil requirements also mean fewer oil transports from the refineries - and the oil does not have to be disposed of in a time-consuming manner. More information under Clean Production

- Energy-savings

EVVA is already purchasing 100% renewable electricity at the headquarters, but is taking additional measures to generally increase energy efficiency. For more information, see Power Management system. We also generate energy ourselves from solar power via our PV systems. The photovoltaics section has more to offer

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?