ESRS Index

EVVA voluntarily follows the ESRS standardsThe European Sustainability Reporting Standards (ESRS) are a comprehensive guideline for sustainability reporting.

Dear readers, dear

stakeholders, thank you for your interest in our environmental, social and governance strategies and measures. This report informs you about the EVVA Group’s commitment to sustainability. EVVA prepared a sustainability report back in 2005 - as one of the first companies in the industry worldwide. Since 2011, we have been reporting according to GRI (Global Reporting Initiative). EVVA is not subject to ESRS (European Sustainability Reporting Standards). However, in this voluntary report, we are aligning with the new ESRS standards - both in materiality analysis and sustainability reporting from the 2024 reporting year onwards.

ESRS 1 defines formal requirements that are not specifically listed in the index. It starts with general information ("ESRS 2") and then provides information on the topics defined by EVVA as essential in the standards “E1 Climate Change”, “E5 Resource Use and Circular Economy”, “S1 Workforce in the Company” and “G1 Corporate Governance”.

We wish you an interesting and inspiring read!

When considering its key sustainability topics, EVVA has taken into account its own business activities as well as the upstream and downstream value chain.

The company’s own business activities include its headquarters in Vienna and its own subsidiaries in nine other countries in Europe. The focus of the reporting is on the EVVA headquarters and the EVVA Power Plants (= production sites with significant production processes), which are the production sites in Vienna, Krefeld and Tišnov. Focusing is done for these reasons:

- EVVA’s main production facility is located at its headquarters in Vienna. This is where most of the production value creation takes place throughout the entire Group. At the headquarters, the entire production of raw parts, the production of all electronic EVVA access systems and the production of large customer orders are also carried out for subsidiaries. The headquarters also procures virtually all materials and product components for the entire international group via the “Logistics and Purchasing” area

- EVVA is including the two other smaller power plants in Krefeld (Germany) and Tišnov (Czech Republic) in the sustainability declaration. Together, all three EVVA production sites - Vienna, Krefeld and Tišnov - account for 95% of the Group’s production value creation

- The other EVVA locations (complete overview at www.EVVA.com/at-de/ueber-uns/kontakt/international ) are European sales offices that can carry out assembly activities, but have no or very few machines. Their number of employees ranges from 10 to 25 persons. The sustainable impact is very low at these subsidiaries

- The vast majority of raw materials and resources, namely 95%, are purchased via the Vienna headquarters for all EVVA branches. As the inflow of resources is therefore practically only driven via one location, the data specified in “E5 Resource use and circular economy” refers to EVVA headquarters. The remaining 5% are marginal in the overall view

- The upstream and downstream value chain is only defined as material for “E1 climate change” and greenhouse gas emissions. EVVA procures 97% of its materials (mainly brass) from the EU and Switzerland. From countries with very high legal environmental and social standards, which has identified further negative impacts and risks - e.g. on human rights - as low and not material

Key performance indicators

- Emission factors for “E1 Climate change”:

Scope 1 and Scope 2 are calculated by EVVA itself. The CO2 calculations for Scope 3 are carried out using the ecoinvent database and any estimated values. Methodological basis:

> ecoinvent database version 3.10 and 3.11, which provides comprehensive data to quantify greenhouse gas emissions

> For Scope 3: “Use of sold products”: The service life of the mechanical cylinders is 30 years according to the EPDs (Environmental Product Declarations), the electronic products were estimated at 15 years (due to the necessary updates); “Capital goods” had to be roughly estimated due to missing manufacturer information

- Risks have been assessed for our climate analysis.

Methodological basis for the assessment of the following climate risks:

> for storm and tornado: ADAPT (Assessment and Design for Adaptation to Climate Change), a methodology that identifies and assesses risks caused by climate change

> for drought: Aqueduct, a tool from the World Resources Institute to assess water-related risks

> for coastal erosion, soil degradation, soil erosion, subsidence and solifluxation (surface removal on slopes): Copernicus EGMS (European Ground Motion Service), which can monitor ground movements and be used to assess geophysical risks

> for potential hazards due to natural hazards such as floods, earthquakes, storms, hail and snow in Austria: HORA (Natural Hazard Overview & Risk Assessment Austria)

> for climate change data and analysis: Gerics (Climate Service Centre Germany)

Accuracy of estimates:

The accuracy of the key performance indicators shall be at least NUTS 2. NUTS (Nomenclature des unités territoriales statistiques) allows for the assessment of climate risks at regional level. NUTS 2 refers to medium-sized regions, so it is more finely broken down than an assessment at national level

- In the financial analysis of risks and opportunities, the extent threshold is based on qualitative assessments of our manufacturing company compared to other companies of similar size

Changes or errors in sustainability information

For the first time - and voluntarily - EVVA is preparing a report based on ESRS in the 2024 reporting year. Many key performance indicators, e.g. for the Scope 3 calculations, have been analysed in a new and more comprehensive way. Therefore, a comparison with the figures from the old sustainability reports according to GRI is also not meaningful. Future possible changes or errors will therefore not be reported here until the next reporting period.

Number of managing and non-managing members

All members are independent in their decisions. The two works council chairs (for employees and blue-collar workers) represent the employee side on the Supervisory Board.

| Administrative and management bodies | Supervisory bodies | Of which female | Of which male |

|---|---|---|---|---|

| Number of managing directors | 1 | 0 | 0 | 1 (100%) |

| Number of non-executive members | 1 | 5 | 3 (50%) | 3 (50%) |

Experience of management bodies

The company’s management - which is also the owner of the family-owned company EVVA - is the third generation to run the company. Nicole Ehrlich-Adám has been with the company since 1987, Stefan Ehrlich-Adám since 1993. The ancestor, Carl Grundmann, played a decisive role in building up the European security industry in the 1860s. Her experience in corporate management in general and in the European security industry, as well as with mechanical, electronic and mechatronic access solutions in particular, can be described as particularly comprehensive.

The management has the necessary competences for their area of responsibility. The Supervisory Board and Management Board participate together in the ongoing strategy meetings and exchange information on EVVA’s sustainable strategies and important legal framework conditions.

The members of the Supervisory Board have many years of experience in corporate management and project management. You work in leading positions as CEO in major companies and in Corporate Finance. The works councils on the Supervisory Board are trained specialists and have been employed by EVVA for decades.

Roles and Responsibilities

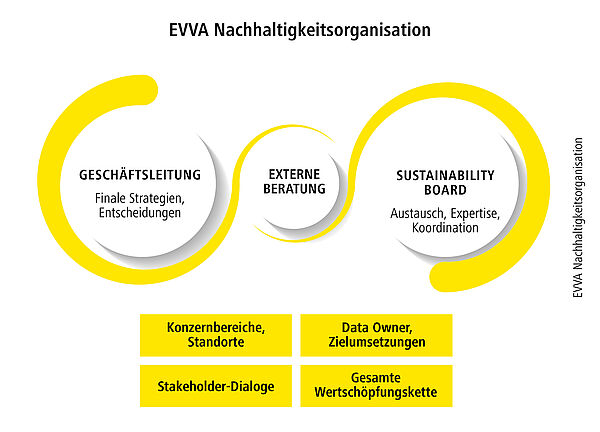

Sustainability management is coordinated by the EVVA Sustainability Board and is anchored at the highest decision-making level in EVVA’s management. It takes into account economic, environmental and social impacts in all decisions. Senior management is a member of the Sustainability Board and participates in all procedures relating to material impacts, risks and opportunities. Such as materiality analysis, risk analysis, strategy meetings, status meetings on the sustainable goals, etc.

The impacts, risks and opportunities are assessed by the management with the support of the Sustainability Board. EVVA’s Sustainability Board consists of 10 permanent employees from different Group divisions (the board can be expanded if necessary). As specialists, you are responsible for important sustainability aspects - such as management, finance, production, energy management, Risk management, purchasing/logistics, occupational safety, compliance, Standards and communication/reporting.

In addition to management, all members of the Sustainability Board participated in the multi-day materiality analysis workshops. They coordinate the relevant key sustainability topics, set goals, review measures and monitor successes. Management is directly involved in all processes and decisions.

Expertise to monitor sustainability aspects

The management possesses the expertise and interest related to sustainability - it itself initiated the first EVVA sustainability report in 2005. EVVA’s Sustainability Board contributes additional expertise from the various zones. Management and the Board keep up to date on the new features and developments:

- External consultation: EVVA has been working with external sustainability consultancies for many years, most recently with BDO. The consultants support EVVA with procedures (e.g. for materiality analysis and climate risk analysis) and present further developments. Management has participated in all workshops to determine the key topics

- Dialogue formats: EVVA is a member of sustainability initiatives (such as respACT), in which a wide range of sustainable aspects in the value chain are stimulated and discussed. Management and members of the Sustainability Board attend events, webinars, etc. part

- Internal exchange: The top management level exchanges views on current and material topics in regular status reports for the sustainability goals and the strategy and group division meetings, which take place several times a year. Sustainability is a fixed point in meetings

Sustainability-related information to the management bodies

EVVA’s management is kept up-to-date on the status, progress and effectiveness of the activities by the Sustainability Board in target meetings held several times a year. Management is informed about all impacts of EVVA that could be critical for people and the environment (inside-out) and impacts on EVVA that could be critical for financial business development (outside-in). It communicates these material aspects to the Supervisory Board and discusses these topics with it in regular sessions.

Below is a list of EVVA communication channels in which sustainable impacts, risks, opportunities, measures, goals can be discussed or hazards and improvements can be reported. In many cases, management is personally involved. In other cases, it will be informed promptly by the departments involved.

Internal information channels (frequency per year in brackets):

- Materiality analysis (annual update check)

- Risk analysis (1 x annually and as required)

- Sustainability Board meetings incl. status of sustainability goals (2-3 x and if necessary)

- Legal Compliance Meetings (5-6 x)

- Works council meetings with HR/management (4 x and if necessary)

- Supervisory Board meetings (4 x and as required)

- Strategy workshop (1 x)

- Strategy day (1 x)

- Strategy talks (ad hoc)

- Branch office conference with site managers (2 x)

- Divisional workshops (several times a year)

- Economic forecasts from the Market Innovation & Technology Group division (1 x)

- Trend radar (1 x)

- and other internal dialogue formats listed below "ESRS 2, SBM-2 Stakeholder

External information channels:

- Technical committees at European level, such as the ARGE/works council for locks and escutcheons (1x)

- National trade associations and interest groups, such as industrial associations and the Chamber of Commerce (ongoing meetings and sessions)

- Networks for innovation, sustainability and other specialist topics, e.g. respACT, Sustainability Circle, INNOX, corporate competitions, etc. (ongoing events)

- External trend analyses for individual business units (1 x)

- Telephone satisfaction surveys among business partners in which negative effects can be discussed (ongoing)

- Stakeholder exchange with customers and partners, e.g. during tours and sales events/visits or joint innovation processes, etc. (ongoing)

- Feedback from EVVA test systems

- Cooperations with other companies (ongoing)

- Policy and Social Partnership: EVVA CEO Stefan Ehrlich-Adám is an active member of the employer’s representative body in collective bargaining for the Austrian metalworking industry. These take place every autumn with the employee trade union representatives. Complaints, demands and wishes from the trade unions are brought directly to him and the negotiation team of employer representatives and discussed intensively. Every year, a consensus was reached with the trade union representatives

Significant impacts, risks and opportunities addressed by management bodies

The topics defined accordingly in the materiality analysis are listed under SBM-3. The identified significant impacts, risks and opportunities are incorporated into the overall strategy.

There are no incentive schemes for sustainability-related performance for administrative, management and supervisory bodies.

Management performs due diligence, including materiality and risk analyses, in order to prevent possible damage. Due diligence encompasses the process of identifying actual and potential negative impacts on people and the environment - and how a company acts to prevent or reduce them. EVVA’s duty of care is based on the OECD guidelines. EVVA’s approach includes:

1. EVVA policies and strategic principles

They anchor our sustainable, responsible actions. In addition to the vision, mission statement, values and Code of Conduct, EVVA develops its own policies on sustainability aspects, such as

- EVVA Human Rights Policy

- EVVA Diversity Policy

- EVVA environmental policy

- Code of Conduct for employees and business partners

- Whistleblower tool for employees

The policies can be accessed at https://www.evva.com/at-de/ueber-uns/unternehmen/#tab4 www.evva.com/at-de/ueber-uns/unternehmen/.

2. Materiality and risk analyses

EVVA analyses and assesses its actual and potential impacts on people and the environment as well as risks and opportunities. Details on this - and how EVVA involves internal and external stakeholders - are explained in particular under the following points IRO-1, SBM-2 and SBM-3.

3. Avoiding or reducing significant negative impacts

EVVA implements numerous measures with targets for this purpose. More on this under SBM-3 and in the essential topic-specific standards E1, E5, S1, G1.

4. Follow-up on implementation

EVVA evaluates the targets set and their respective status in the Sustainability Board’s sustainability target meetings. The effectiveness of the results is also discussed.

5. Communication

The annually updated sustainability report describes which impacts are dealt with and how. In addition, the topic of sustainability is present in EVVA’s analogue and digital media channels (e.g. internally in intranet news and employee magazine or externally in newsletters and social media).

6. Compensation if necessary

Should damage occur that was caused by EVVA (or not caused, but can be prevented in the future), EVVA will do everything in its power to eliminate or minimise it (e.g. GHG emissions) and implement appropriate precautionary measures.

EVVA fulfils its duties of care with risk assessments and analyses in order to prevent possible environmental, health and economic damage. The risk analysis - coordinated by the “Quality Management” staff unit for the entire company - is part of the double materiality analysis. It identifies hazards for the company and describes and assesses them. EVVA has also carried out a comprehensive climate risk/climate resilience analysis. Risk assessment and prioritisation is described in IRO-1. The result of the double materiality analysis including climate risk analysis is documented under SBM-3.

EVVA’s existing risk assessment includes risk descriptions and includes all corporate units - from personnel to market/sales and compliance. Existing risks have been reconciled with themes and sub-themes of the ESRS standards, assigned and, if necessary, expanded or clustered. An opportunity analysis has been added and the threshold value for evaluation has been defined more precisely.

The internal control of sustainability reporting in relation to targets and measures is taken into account by those responsible in the Sustainability Board, in which the management is also represented.

Products of interest

The EVVA product portfolio includes high-quality mechatronic access control solutions and can be accessed at any time on our website www.EVVA.com. The most important EVVA products are security systems

- with mechanical keys, such as MCS (magnetic code system) or Akura 44

- with electronic keys or access media such as Xesar or AirKey

- and a combination of mechanical and electronic EVVA solutions, which are made possible by a mechatronic hybrid key, for example

EVVA produces around 1.5 million mechanical security cylinders and around 6 million keys per year. In addition, many tens of thousands of delivered electronic components such as wall readers or e-cylinders as well as access media.

Significant markets and customer groups

- EVVA is represented in Europe with its own subsidiaries and worldwide with distributors. The markets supplied are listed at https://www.evva.com/int-en/aboutus/contact/international/

- EVVA products are suitable for all industries, a selection can be found on the website at https://www.EVVA.com/int-en/solutions/

- The most important region for EVVA’s sustainability goals is (Central) Europe

- The most important customer groups are trade partners (security specialists and key services) who sell EVVA products to companies and private individuals. General contractors and architects/planners usually want to be in contact with manufacturers, which is why EVVA also works directly with them

Number of employees by geographical area

See Employee Satisfaction (ESRS S1-6)

Total revenue

The EVVA Group’s total revenue in 2024 amounted to 98 million Euro.

Sustainability targets

Our sustainability goals contribute to our competitiveness. They minimise our impact on people and the environment, tap into market opportunities and create a high level of trust among our stakeholders in EVVA.

The sustainability goals basically refer to all internally manufactured products such as security cylinders and keys in the three power plants in Vienna, Krefeld and Tišnov as well as to the most important stakeholders in the upstream value chain in the EU. Our key sustainable pathways include emission and energy reduction, an advanced circular economy, comprehensive occupational safety and corruption prevention. For a complete overview, see Our Objectives.

Elements of the strategy that concern sustainability aspects

EVVA is a pioneer in sustainability and has been reporting on its ESG activities since 2005. As a family business, we think for generations. EVVA lives a meaningful business model and takes measurable responsibility for people and the environment. For example, with the net-zero target in Scopes 1 and 2 - i.e. in the areas in which we have control. For Scope 3, we work closely with key suppliers to make progress outside our own value chain.

Our overarching sustainability aspiration is to be a reliable partner for our employees, trading partners and all stakeholders and to make an effective contribution to a safer, more environmentally conscious society. We owe this not only to future generations, but already even to our generation today. Sustainability must therefore be an integral part of the corporate culture and is firmly rooted at EVVA in

- our Code of Conduct for employees and business partners. The Code of Conduct contains clear rules for lawful business practices, anti-corruption, fair competition, environmental responsibility and appreciative, respectful treatment

- the policies for the environment, human rights and diversity (available at https://www.evva.com/at-de/ueber-uns/unternehmen/#tab4)

- in environmental policy with clear guidelines, such as using raw materials and energy sparingly, avoiding emissions and waste as far as possible and increasing environmental awareness through information and dialogue with stakeholders

- our corporate vision as a “reliable companion”, which EVVA emphasises not only for economic reasons, but also because we are aware of our responsibility towards the environment and people. EVVA is also a reliable companion and implementer when it comes to the Green Deal and human rights

- our established values (as part of the “EVVA culture box”, which is handed over to every employee upon joining)

- and in the EVVA mission statement. It implies qualitative characteristics that are also reflected in the ESRS standards, such as relevance and comprehensibility:

> Only by listening - understanding - solving, i.e. by exchanging with internal and external stakeholders, can effects, risks and opportunities be identified

> Simple is better than complicated. We have also tried to report everything as clearly and comprehensibly as possible in the sustainability report

> Take responsibility yourself. Divisional goals and individual goals for employees must take sustainability into account. They are discussed in the employee orientation meetings (MOGs) between the manager and employee

> Objective, costs & benefits. EVVA sets sustainability goals that are pursued, implemented and monitored. They always have a clear benefit. A claim that is reflected in the first sentence of the mission statement: We inspire our partners and customers. And hopefully our planet

In principle, sustainability affects all areas and strategies of a company. The most significant impacts for EVVA concern corporate governance, occupational safety, production, purchasing and energy management.

Description of the business model and value chain

Business model:

EVVA is a renowned European manufacturer of mechanical, electronic and combined mechatronic access solutions. The company was founded in Vienna in 1919 and is still a family business today.

The distinctive inventive spirit, with currently well over 400 patents, is already in the company’s name: Invention, test and evaluation institution. We invent and develop products that guarantee highly secure access. We manufacture these innovations ourselves to a very high standard of quality and service life. EVVA products can secure generations, EVVA also receives reorders of products that have already been in use since the 1970s or earlier. In addition to our customers from all industries, our around 10,000 business partners and distributors also rely on proven EVVA security. EVVA sells its products and services primarily through these partner companies - such as security specialist stores and key services - that offer our access solutions to international companies and private customers. With general contractors, developers, etc. EVVA is also in direct contact.

EVVA is pushing for mechatronic access solutions, i.e. the combination of mechanical and electronic systems. The market trend is also moving in this direction. In addition to the tried-and-tested mechanical solutions, electronic systems are becoming increasingly popular for managing access, e.g. with smartphones. EVVA has launched solutions developed by its in-house R&D department on the market and is constantly equipping it with extensions and updates. They complement the foundation of mechanical security and offer advantages such as quick changes to access authorisations, documentation of accesses or special ease of use.

The electronic EVVA solutions also expand the existing mechanical product range of the trading partners and attract new end customers. Since EVVA launched its own electronic security systems Xesar and AirKey on the international market, the number of EVVA partners who also offer electronic security technology has multiplied. EVVA is thus promoting the further development and increase in sales of the industry.

EVVA’s revenue model includes the development, production and sales of these mechanical, electronic and combined access solutions.

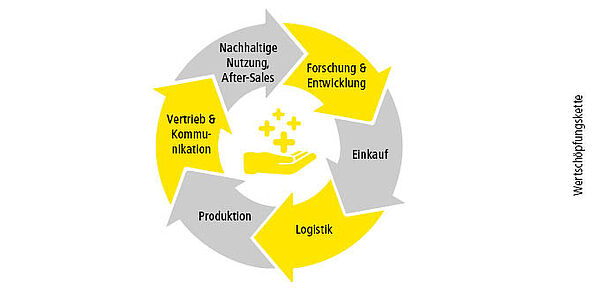

Value chain:

The business model and the determination of the essential sustainable topics consider the entire value chain - the upstream and downstream as well as the company’s own business activities. So from product development to purchasing and production to product use. Examples of this include:

- Research&Development comprehensive innovation management; Product development also together with stakeholders; Use of more energy-efficient product components

- Purchasing: high proportion of secondary materials, in particular recycled brass, necessary for the manufacture of the products; Reduced need for oil and water thanks to clean production

- Logistics: Very high share of regional suppliers of 97% for shorter transport routes, increased share of reusable pallets

- Production: High clean production share of 80% (to manufacture without oil and water); energy efficiency and emission reduction measures; disassembly of own photovoltaic systems; Improved compressed air system

- Sales & Communications: environmentally friendly packaging; Stakeholder dialogues, digital order managment strongly expanded

- Sustainable use, after-sales: durable EVVA products with often decades of use; Satisfaction surveys

Benefits for stakeholders

EVVA offers a comprehensive portfolio of high-quality and durable products as well as services such as locking system software or installation services. Most important physical outputs are security cylinders and keys. Our output is aligned with the needs of stakeholders such as customers and trading partners. Your EVVA benefits include

- for trading partners: Access to environmentally friendly and innovative security solutions

- For Customers: Reliable, durable products - for mechanical cylinders 30 years according to Environmental Product Declaration (reference service life with 100,000 test cycles)

- for investors and lenders: secure business model and long-term value creation

- for people and the environment: Measurable effective measures for climate protection, CO2 neutrality, conservation of resources, occupational safety and fair competition (see the following topic-specific standards E1, E5, S1, G1)

Key features of the upstream and downstream value chain

Upstream value chain:

- Brass is our main manufacturing material. The proportion of brass in the total metal requirement is approx. 80%. Over 90% of our needs are covered by purchasing recycled materials

- Raw materials and resources are purchased for the vast majority, namely 95%, via the Vienna headquarters for all EVVA branches

- Very high share of regional suppliers of 97%. All come from the EU or Switzerland. EVVA defines a radius of 1000 km as regional. Read more about our supplier relationships under Share of regional suppliers.

Downstream value chain:

- By customers we mean our thousands of partner companies - such as key services and security specialist stores - that sell EVVA access solutions to companies, authorities and end customers worldwide. EVVA works with general contractors, architects, etc. also in direct exchange

- EVVA offers its partner companies a digital ordering platform, decoration and information materials for their specialist stores, further training courses on security technology and joint personal events and lectures

- EVVA involves trading partners in product development. This enables innovations to be realised that better meet market requirements. This shows an example of how the parts of the value chain are interlinked and connected

Very important stakeholders for EVVA’s sustainability include our employees, our trading partners through whom EVVA offers its access solutions, our suppliers as well as the Supervisory Board and research institutions. The stakeholder groups and their involvement are described in detail below.

Stakeholder engagement

Number of staff:

- Cross-departmental networking events (branch conferences, annual kick-offs, sustainability board meetings, innovation management, etc.), several times a year

- Stakeholder dialogues (incl. works council) for materiality analysis for sustainability report

- Info breakfasts/info cafés at all locations: Personal dialogue between management and employees and managers on current developments and topics in the EVVA Group, several times a year. Employees’ questions are answered immediately by management

- Ongoing intra-departmental and inter-departmental meetings

- Employee orientation meetings with a focus on sustainability 2 times a year

- Employee representatives (e.g. at headquarters with several works councils for employees and workers); Works council meetings with HR/management several times a year and as required; Works agreements (e.g. on flexitime) are decided jointly by the works council and management

- several networking events per year, such as Christmas parties, family days, repair cafés, table football tournaments, running events, etc.

- Employee newspaper (digital and print), cross-zone and cross-site editorial meetings

- Intranet with approx. 190 news items per year and internal collaboration platforms with like, comment and chat functions

- Comprehensive onboarding

- Ongoing management training/workshops

- Offer of "collegial advice" for conflict resolution if necessary

- Comprehensive further training programs of the EVVA Academy with final feedback questionnaire and evaluation by the participating employees

- Participation in internal improvement proposal initiatives

- internal cross-departmental EPOS teams (EVVA production system), which also suggest and implement sustainability-related optimisation projects within the company

- Employee surveys

- EVVA Compliance Line: a whistleblower tool through which employees can also raise concerns anonymously, e.g. about possible unethical behaviour or risks

Trade partners:

- Stakeholder dialogues on materiality analysis for sustainability report

- Satisfaction surveys (security specialists, key services, etc.)

- Integration in product development, user experience; Exchange between EVVA product developers and representatives of stakeholders already at the concept stage

- "Golden Events" with sales and team-building workshops several times a year

- Ongoing product and application training at the EVVA Academy

- Regular personal support and visits by EVVA sales employees

- Continuous feedback to EVVA on customer needs

- Digital partner portal and regular newsletters

- Personal support for general contractors and trading partners

- Factory tours

The Supplier:

- “EVVA Business Partner Check” - a questionnaire sent to selected suppliers for self-assessment

- EVVA Code of Conduct for business partners

- Involvement of the three most important suppliers in the climate risk analysis

- Regular quality management and coordination meetings, e.g. for the purchase of recycled materials

- Factory tours

Research institutions:

- EVVA has been in close contact with research institutions such as the Vienna University of Technology, the Vienna University of Technology, the CDP (Centre for Digital Production), the Fraunhofer Institute, etc. for decades. Many product innovations such as the Mechanical Magnetic Code System (MCS) have been developed in cooperation with universities and research institutions. Digitally supported production processes are also being developed together

- Stakeholder dialogue on materiality analysis for sustainability report

- Factory tours

Board of Directors:

- Supervisory Board meetings with EVVA management at least 4 times a year

General contractors, end customers; Architects, planners:

- personal support by EVVA and partners together

- personal support of end customers by our partners

- Factory tours

Contracting authorities:

- Ongoing exchange

Media & Press:

- Regular visits/reporting, press releases

- Personal exchange (e.g. at trade fairs)

- Factory tours

Associations & interest groups:

- EVVA CEO Stefan Ehrlich-Adám is Industry Division Head at the WKO and Chairman of the Industrial Association’s Labour and Social Affairs Committee: Personal ongoing commitment to industry, sustainability, education, etc.

- Member of the respACT sustainability platform. Regular replacement; Participation in lectures, workshops, surveys on current sustainability topics, etc.

- Annual exchange with the City of Vienna for the Top Learning Company Award

- Overview of EVVA cooperations under cooperations and partnerships

Local communities:

- Support and personal exchange with the children’s protection association “ die möwe ” for over 10 years

- Personal exchange/job shadowing/company tours with pupils and entire school classes ( www.schuelergestaltenwandel.at ) on the topic of sustainability

- Participation in daughter days

Anrainer:

- Factory tours, as necessary

Purpose of Inclusion

- Exchange and confirmation of strategic sustainable directions and decisions

- Collect, evaluate and implement product and improvement ideas

- Improving collaboration

- Maintaining and building reputation and trust

- Review performance and foster feedback culture

- Increase satisfaction with the company

EVVA has defined the following sustainability topics as material

| Topic | Therefore defined as essential | Value chain (and zone) | Type |

|---|---|---|---|

Upstream/downstream | EVVA needs resources (especially brass) whose production emits greenhouse gases | upstream (manufacturing at suppliers in the EU) and downstream (transport routes) | negative impact (actual) |

| Your own Greenhouse gas emissions (E1 Climate change > Climate protection) | The production of access solutions emits greenhouse gases | own (via heating and vehicle fleet, mainly in power plants in Vienna, Krefeld, Tišnov) | negative impact (actual) |

| Power supply current (E1 Climate change > Energy) | Production has a correspondingly high power consumption | own (production in Power Plants Vienna, Krefeld, Tišnov) | negative impact (actual) |

| Own energy saving measures as an opportunity (E1 Climate change > Energy) | Energy-saving measures can quickly pay for themselves and save energy costs and greenhouse gases | own (production in Power Plants Vienna, Krefeld, Tišnov) | Opportunity (Actual) |

| Resources for the production of EVVA products (E5 Circular economy > Resource inflows, including resource use) | EVVA needs resources that do not fully return to the cycle | upstream (purchasing from suppliers in the EU) and own (production at headquarters in Vienna) | negative impact (actual) |

| Possibility of corruption (G1 corporate governance > corruption, bribery) | Corruption and bribery could occur in one’s own business activities | own (exposed functions) | negative impact (potential) |

| Health and safety at work (S1 Company Workforce > Working Conditions > Health and Security) | In a production company like EVVA, employees are exposed to hazards that can endanger their health and security (assembly, electroplating, etc.) | own (production at sites in the EU) | negative impact (actual) |

The impacts can be over the entire time horizon, i.e. short, medium and long term.

Detailed description

Significant effects:

- Greenhouse gases (GHG) arise in the upstream/downstream value chain:

Brass is our most important production material and is required for the production of our security cylinders and keys in larger quantities. Brass production at our suppliers causes correspondingly high GHG emissions with negative impacts. “Purchased goods” is therefore our largest Scope 3 factor - and thus also a lever for GHG reduction targets.

Transport also emits GHGs. The transports to EVVA (e.g. from the brass supplier) have a larger scope of delivery per trip, but since there are only a few trips, they also cause less GHG emissions. EVVA’s transports (e.g. to subsidiaries or trading partners) include smaller delivery quantities, but more frequent single trips.

Significant assessment in terms of extent (the value chain of industry has higher emissions than many other industries), scope (because transnational/global) and invariability (CO₂ degrades very slowly in the atmosphere)

- GHGs are generated in our own business activities:

EVVA itself emits GHGs via heating and its vehicle fleet in its own business activities. Although they are lower compared to larger industrial companies, they have a negative impact on the global climate. While we’ve been reducing our self-induced Scope 1 share for years (and already switched to 100% green electricity at headquarters for Scope 2 in 2022), efforts are still needed to achieve our self-set Scope 1 net zero target.

Significant assessment in terms of scope (since transnational) and unchangeability (CO₂ degrades only very slowly in the atmosphere)

- Own higher power consumption:

As a production company, EVVA consumes more electricity than companies of similar size in many other industries. While new machines provide more efficient manufacturing processes and replace many old oil-based installations, increasing digitalisation and the connected machinery fleet require more energy. Our ongoing switch from gas to electricity will also reduce our GHG share in Scope 1 on the one hand, but also increase electricity demand on the other. EVVA is trying to counteract this negative impact with its own clean energy sources and cost-saving measures. Even if Net Zero can be achieved in Scope 2 by purchasing 100% green electricity, the demand for electricity in Europe can be better limited if companies take additional initiatives.

Significant assessment in terms of extent (electricity consumption in industry is higher than in many other industries) and scope (since transnational)

- Own resource consumption that does not fully return to the cycle:

As a production company, EVVA has a high resource requirement, and the materials do not fully return to the cycle. This concerns purchasing (e.g. for brass, paper, etc.) in order to manufacture and to pack products, as well as the potential for conserving resources in the core business. EVVA already relies heavily on recycling in order to reuse the materials used as well as possible, but the path to a closed circular economy is winding.

Significant assessment in terms of extent (as a production company, higher resource requirements), scope (national and in upstream value chain, transnational) and invariability (the path towards a closed circular economy is challenging, not easy to influence)

- Potential for corruption, bribery:

The materiality analysis has identified corruption/bribery as a potential impact that could occur in our own business activities. This is why EVVA has assessed this governance issue as material and is increasingly planning preventive measures.

Significant assessment of extent (potentially greater impact on society)

- Industrial accidents in production:

In a production company like EVVA, employees are particularly exposed to hazards that can jeopardise their health and security, for example in assembly or electroplating. Even if the annual accident statistics at EVVA do not show any major fluctuations, every work-related accident can possibly be avoided too often and with even better protective measures - beyond the legal provisions.

Significant assessment of extent (higher in one manufacturing company than in other industries)

Significant opportunity:

- Fast payback of energy saving measures:

EVVA’s analysis has shown that energy-saving measures can bring not only environmental benefits, but also a rapid return on investment, i.e. that the investment costs are recovered after a short period of time. One example is the switch to new compressors with waste heat utilisation at the EVVA headquarters: The investments pay for themselves after just a few years due to the lower energy costs. This shows that measures with an excellent cost/benefit ratio for people and the environment are possible and should be analysed.

The definition as a significant opportunity was made due to the high probability of occurrence, the financial positive effects may also be lower

Influence on business model, value chain, strategy

EVVA’s significant impacts primarily influence its own business activities and upstream value chain. Greenhouse gas emissions can only be reduced further if EVVA itself implements intensive measures and enters into dialogues and cooperations with suppliers to intensify decarbonisation and the circular economy with secondary materials. The business model remains unchanged, but the strategies are aligned with the company’s own targets, such as the reduction of greenhouse gas emissions.

EVVA is professionalising its energy management in order to obtain exact consumption analyses and thus further energy saving potential. This is already bearing great fruit: Switching to more energy-efficient compressors (which generate the compressed air needed for the production of security cylinders and keys) and utilising their waste heat significantly reduces gas demand.

The recycling rate in production and the secondary material share of the most important resource “brass” are already high. Nevertheless, EVVA is pursuing the goal of enabling further increases in its production and purchasing strategy.

The findings of the materiality analysis also influence compliance issues such as anti-corruption and occupational safety. New training courses and measures for employees are carried out.

Analysis of climate risk/climate resilience

EVVA also carried out a comprehensive climate risk analysis for its own three power plants (Vienna, Krefeld, Tišnov) and for the three largest suppliers by purchasing revenue (they are located in Germany and Austria). The analysis did not identify any climate-related physical risks or transition risks.

The analysis was prepared in October 2024 using a template from the consultancy company BDO as follows:

- Screening locations: EVVA first evaluated the locations to be analysed and identified relevant business partners in the value chain

- Screening hazards and system elements: Individual climate hazards have been identified based on the geographical location of the EVVA locations, assigned to the system elements (such as employees, storage areas, production machines) and then evaluated. Aqueduct, Gerics, HORA or ADAPT, among others, served as platforms for current data (more information on these tools under BP-2)

- Screening climate scenarios: EVVA has prepared the climate scenario analysis using the BDO evaluation tool per location and system element and analysed it for the scenarios rcp 2.6, rcp 4.5 and rcp 8.5 (see next paragraph for rcp explanation)

- Assessing the risk In the last step, the identified hazards were again assessed according to the extent of damage and probability of occurrence using the internal risk graph. The following time horizons are defined: short-term to 1 year, medium-term 1 to 5 years and long-term 5 to 45 years. The materiality threshold was defined as 3% of sales.

With the help of the evaluation tool, high percentage changes were then examined in more detail and checked against other sources. In the event of a significant impact, measures would be derived; however, no material topic was identified in the monetary risk classification

Explanation of the rcp (representative concentration pathway):

rcp are the climate scenarios developed by the IPCC.

- rcp 2.6: Scenario where the increase in the global average temperature up to 2100 remains limited to 1.5 to 2 °C compared to pre-industrial levels. It is the most ambitious and favourable scenario for climate protection and comes closest to the Paris Agreement limiting global warming to +1.5°C. 2.6 refers to the so-called radiation drive, which describes the change in the Earth’s energy balance. 2.6 W/m2 means that the earth absorbs 2.6 watts more energy per square metre than it emits. This leads to greenhouse gas concentrations in the atmosphere and global warming. According to the Paris Agreement, warming remains within acceptable limits for people and the environment in a 2.6 scenario

- rcp 4.5: In this scenario, global greenhouse gas emissions will increase by around 2040 and stabilise by 2100 at a level that limits warming to +2.5-3°C

- rcp 8.5: This scenario assumes continued high growth in greenhouse gas emissions, leading to global warming of around +5°C to 2100 compared to pre-industrial levels

Dual materiality analysis allows an organisation to identify and assess its most significant impacts, risks, or opportunities. EVVA has applied the procedure in accordance with ESRS.

- The impact materiality identifies and evaluates impacts on people and the environment from EVVA (inside-out perspective). The GHG emissions for all three scopes were determined in accordance with the GHG protocol. The calculation was made by EVVA and with information from external suppliers

- The financial materiality identifies and assesses financial risks and opportunities that have an external impact on EVVA (outside-in perspective)

- The procedure for the additional climate risk analysis carried out is described in more detail under SBM-3

1 Our impact materiality procedure

EVVA conducted the impact materiality analysis in a two-day workshop in 2024. One day of the workshop was dedicated only to environmental issues, the other to social and governance issues. 14 EVVA experts, most of whom from the Sustainability Board, took part and represent Group divisions and core sustainability-relevant tasks at EVVA (management, production, Logistics & Purchasing, Research & Development, Innovation Management, Technology Management, Energy Management, Compliance, Digital Services, Finance, Quality and Process Management, Human Resources & Organisational Development). The sources for the determination are the themes, sub-themes and company-specific themes covered in the ESRS as well as the UN’s Sustainable Development Goals (SDGs). An internal pre-compiled list of possible impacts also served as inspiration and guidance.

The workshops started with an ESRS introduction to ensure the same level of knowledge for all participants. The goal of the workshop was clearly communicated and noted on posters that were visible to everyone at all times during the analysis: to identify positive and negative effects of the EVVA Group on people and the environment along the entire value chain. Subsequently, the assessment process for impact materiality was explained in detail. The consultancy company BDO provided EVVA with helpful information for carrying out the materiality analysis.

Evaluation and prioritisation:

The identified ESG (Environment, Social, Governance) topics are categorised into positive or negative impact; actual or potential; on people, the environment or both; Time horizon; Country; value chain or own business activity. The impact assessment was carried out by specialists and management according to these criteria:

- Dimensions:

1 = minimum; 2 = weak; 3 = large; 4 = significant.

The threshold is based on our qualitative assessments as a manufacturing company compared to other companies. Emissions, electricity consumption, resource inflows or work accidents at EVVA are low globally or nationally, but can be higher compared to non-producing companies of similar size and therefore rated above average. In the case of GHG emissions, in our view, a threshold is secondary in that the Green Deal target provides for a CO2 neutral EU by 2050, in Austria by 2040. So GHG emissions - regardless of whether they are low or high - should be classified as material by each company so that this target can be achieved together

- Scope:

1 = affects a small number of people (up to 10) or local area; 2 = moderate number (11-250) or region; 3 = high (251-1000) or state; 4 = very high (over 1000) or EU or global

- Frequency of occurrence (for potential effects only):

1 = very low (every 20-100 years); 2 = low (every 10-20 years); 3 = high (every 2.5-10 years); 4 = very high (every 0-2.5 years)

- Non-changeability/compensation (only in the event of negative effects):

1 = can be rectified quickly or with minor measures; 2 = with some effort; 3 = difficult, high effort; 4 = irreversible, not recoverable

- Ratings above “3” are considered material

2) Our financial materiality procedure

EVVA carried out the analysis of financial materiality in a one-day workshop in 2024. Most impact analysis participants also participated in this workshop. All areas that were particularly important for this analysis were represented, such as management, finance or quality and process management, which coordinates EVVA’s risk management.

The aim of the workshop is to: identify financial risks and opportunities that affect the EVVA Group along the value chain. The assessment process for financial materiality was then explained in detail. Here, too, the consultancy company BDO provided helpful support for implementation.

First, the EVVA risk list identified where an ESG (environment, social, governance) reference exists and then the sustainability-related risks were considered from a gross perspective, i.e. without measures already taken, and assigned to the ESRS topics. The existing risk list was compared with a pre-compiled list of further possible risks and opportunities. Since the previous risk list did not yet include an analysis of opportunities, it was supplemented with this viewpoint.

Evaluation and prioritisation:

The identified ESG topics were classified as already described in the impact materiality. The financial evaluation was carried out in the team under the leadership of the Management Board and the Group Finance Division according to these criteria:

- Potential extent of damage in the event of risk or potential in the event of opportunity:

1 = trivial; 2 = low; 3 = significant; 4 = large; 5 = very high.

The following quantitative information is set as the threshold value: 1 = up to 1% of the revenue of the reporting year; 2 = 2%; 3 = 3%; 4 = 4%; 5 = from 5%

- Probability of occurrence:

1 = very unlikely (up to 1%); 2 = unlikely (1-20%); 3 = likely/possible (21-49%); 4 = very likely (50-85%); 5 = almost certain (over 85%)

- Ratings above “3” are considered material

Management and EVVA experts in materiality analysis

Stakeholder engagement

The determination, evaluation and results of the materiality analysis were discussed in person with representatives of important stakeholders (at EVVA on site or via video conference) in order to ensure that the topics defined as material are understood and comprehensible and can be expanded if necessary. The stakeholders consulted include EVVA works councils, business and production managers of the power plants, trading partners, suppliers and a research institution. The key EVVA topics were confirmed in the stakeholder dialogues.

Periods for materiality analysis

EVVA carried out the double materiality analysis in accordance with ESRS for the first time in 2024. A completely new analysis is not planned in the near future. However, the key topics and their objectives are reviewed on an ongoing basis in the Sustainability Board meetings. If new actual or potential impacts, risks/opportunities arise or are introduced, they are evaluated in accordance with the double materiality analysis procedure.

As mentioned in the introduction, EVVA is not subject to ESRS, but is based on these standards in its sustainability reporting. SBM-3 clearly describes to which ESRS standards the sustainability topics defined by EVVA as material can be assigned. These are the main topics E1 (climate change), E5 (circular economy), S1 (company workforce) and G1 (corporate governance). The following topics are not material:

| Not important at all | Reason |

|---|---|

| E2 pollution; E3 Water and marine resources; E4 Biodiversity and ecosystems | EVVA and the upstream value chain emit significant amounts of CO 2, which is already reported as material in L1. Other hazards such as water pollution or biodiversity losses are low. There has never been any criminal proceedings against EVVA. As 97% of suppliers are located within the EU and Switzerland with high environmental and social requirements, no risks or impacts other than GHG emissions have been assessed as material in the value chain. The south of Vienna, where the headquarters are also located, is a water conservation area. The risk posed by EVVA’s production to biodiversity and groundwater has been assessed as very low and not significant. The business does not deteriorate natural habitats. EVVA also complies with all legal measures and controls. The two other power plants in Krefeld and Tišnov are not located in biodiversity zones. |

| S2 Labour in the value chain; S3 Affected communities | EVVA and 97% of our suppliers are based in the EU and Switzerland with high legal environmental and social requirements. EVVA uses recycled materials to cover around 90% of the most important material, brass. The analysis did not identify any significant risks and impacts related to non-compliance with human rights, social and environmental standards. |

| S4 Consumers and end users | EVVA complies with all regulations, product labelling is correct. There were no violations of the law. All EVVA products are not only tested during the development process and in our in-house test laboratory for functionality, durability or long-term use, but also for safe use. |

Transition plan/milestones for climate protection (E1-1)

The Paris Climate Agreement stipulates that increasing global warming will be limited to 1.5 degrees Celsius compared to pre-industrial levels. This threshold was still considered safe and acceptable by the World Climate Council. To achieve this goal, the EU has declared the Green Deal on greenhouse gas neutrality by 2050.

Link to Science Based Targets:

The Science Based Targets initiative (SBTi) is a collaboration between several international organisations such as the CDP (Carbon Disclosure Project), the United Nations Global Compact, the World Wide Fund for Nature (WWF) and numerous companies. It sets science-based climate targets to ensure that the Paris Agreement is met by limiting global warming to 1.5 degrees Celsius. The following information relates to the SBTi criteria as indicated in these links (March 2024 version): https://sciencebasedtargets.org/resources/files/Getting-Started-Guide.pdf sciencebasedtargets.org/resources/files/Getting-Started-Guide.pdf and https://sciencebasedtargets.org/resources/files/Net-Zero-Standard.pdf

Related to Scope 1 and 2:

- Near-term targets:

> Reduction of emissions by at least 4.2% per year (based on 2020). This results in a total reduction of 42% by 2030

> Achievement of each sub-target in 10 years at the latest (from the start year)

> Max. 5% of emissions can be exempted

> Switching to 100% renewable energy by 2030 (only applies to Scope 2) - Long-term targets: min. 95% reduction by 2050

Related to Scope 3:

- Near-term targets:

If Scope 3 emissions account for more than 40% of total emissions (as at EVVA), “near time” targets must also be set according to SBTi:

> Reduction of emissions by at least 2.5% per year and by at least 67% in 10 years

> Achievement of each sub-target in 10 years at the latest (from the start year)

> Max. 10% of emissions can be exempted - Long-term targets: min. 90% reduction by 2050

In the EVVA Group, the greenhouse gas emissions at the headquarters, which is also the main production site, are the highest of all locations. The emissions reduction targets set by the headquarters are in line with these science-based targets (basis: market-based Scope 2 calculation) - with the exception of the 67% target for Scope 3, achieving this target within 10 years does not currently seem realistic.

EVVA’s reduction targets are stated under CO2 neutrality. Targets for the other two power plants in Krefeld and Tišnov are being analysed.

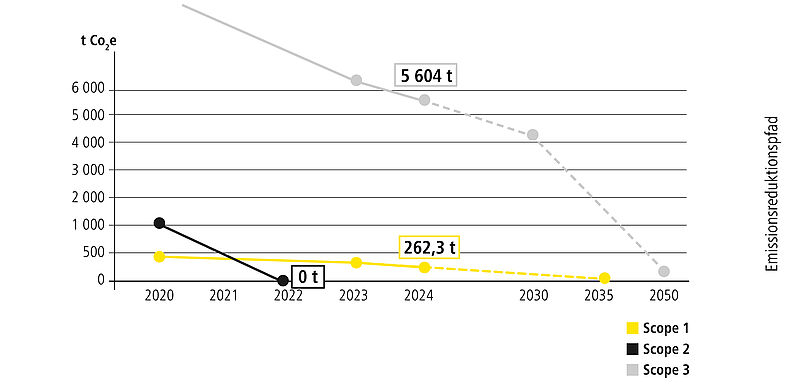

Emissions reduction path

The table shows the emissions reduction path of the headquarters with the main production site and the path towards Net Zero if all measures take effect as planned. EVVA has already been able to reduce CO2 emissions in all three scopes (for Scope 2, taking into account the market-based approach). This is in line with the Paris Agreement on Climate Change in order to limit global warming to 1.5 degrees Celsius and meet the Green Deal in a timely manner - for Scopes 1 and 2 well before the planned EU target year 2050. EVVA has been able to achieve the previous reductions primarily through the following strategies and measures:

- For Scope 1: ongoing conversion from gas to electricity, heat recovery via compressors, increasing share of electric vehicles in the fleet

- For Scope 2: CO2 neutral since 2022 through purchase of 100% green electricity

- For Scope 3: Lower CO2 share for “purchased goods” due to increased recycled content, fewer flights

Our concepts for climate protection and climate change adaptation (E1-2)

see Energy & Emissions Overview

Our actions and objectives (E1-3 and E1-4)

See Energy & Emissions Overview and sub-items

Energy consumption and energy mix (E1-5)

see Energy & Emissions Overview

Gross GHG emissions (E1-6)

see CO2 neutralityhttps://www.evva.com/at-de/ueber-uns/nachhaltigkeitsbericht/unsere-projekte/timeline-detail/co2-neutralitaet/

GHG reduction via CO2 certificates (E1-7)

EVVA has not yet financed the removal of greenhouse gases via CO2 credits. EVVA has not used compensation certificates for its emission targets. Any use is only considered if it is evident where emissions will remain after or during the implementation of the net-zero targets.

Internal CO2 pricing (E1-8)

There are no internal pricing systems in use.

Financial effects of significant risks and opportunities (E1-9)

No material negative risks for EVVA were defined in the financial materiality analysis and the climate risk analysis carried out for three internal and three external locations also did not assess any risks as material (see SBM-3). EVVA has identified the opportunity to quickly save energy costs and greenhouse gases as essential. The materiality of the opportunity is based on the high probability of occurrence, the financial benefit may also be lower.

Our concepts for an active circular economy (E5-1)

see Circular Economy Overview

Our actions to use resources more sustainably (E5-2)

see Circular Economy Overview

Our Objectives (E5-3)

see Circular Economy Overview

Resource inflows (E5-4)

Our concepts for occupational health and safety (S1-1)

see Occupational safety & health protection

Involvement of our employees (S1-2)

see Occupational safety & health protection

Procedures and information channels (S1-3)

see Occupational safety & health protection

Our measures for the protection and health of our employees (S1-4)

see Occupational safety & health protection

Our Objectives (S1-5)

see Occupational safety & health protection

Characteristics of own workforce (S1-6)

see Employee satisfaction

Number of occupational accidents (S1-14)

Our Corporate Governance and Culture Concepts (G1-1)

see Responsible corporate governance

Prevention and detection of corruption and bribery (G1-3)

see Comply with laws, prevent corruption

Cases of corruption or bribery (G1-4)

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?