Regionality = Sustainability

The pandemic and the Ukraine war have reassessed many things. Regionality has been given special importance. Lean global supply chains continue to exist, but proximity to suppliers has become more important. EVVA already focused on value creation depth and regionality before the coronavirus pandemic, because

- making us more independent of distant suppliers, which increases security of supply and reduces possible delivery difficulties in times of crisis,

- shorter transport routes mean less CO2 emissions and thus contribute to climate neutrality,

- working with nearby suppliers helps to keep jobs in the region.

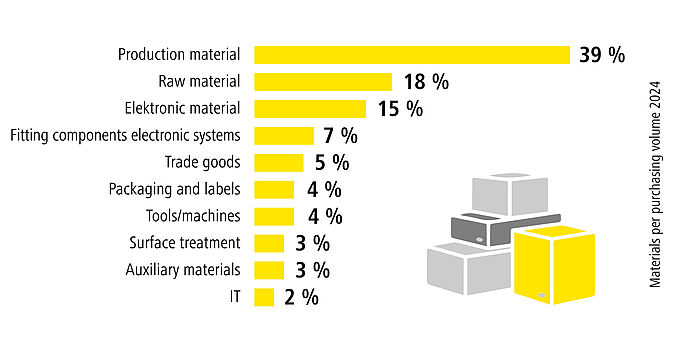

Proportion of suppliers by materials

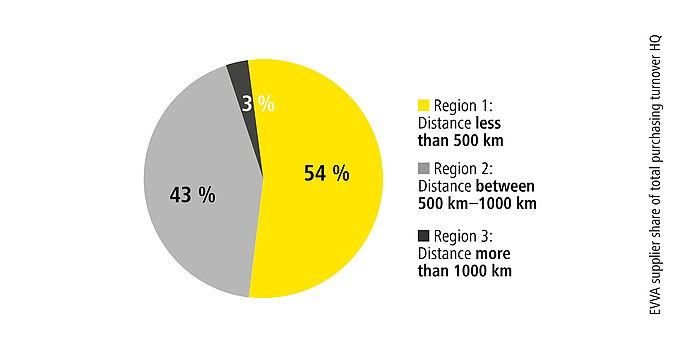

The “Logistics & Purchasing” unit at EVVA headquarters is responsible for central purchasing within the Group and has analysed the regional proximity of suppliers:

- EVVA works with around 400 suppliers to produce high-quality mechanical and electronic access systems. Among other things, they cover our raw material requirements for production (mainly brass) as well as for product components and tools

- Of our top 100 suppliers, 57 come from Austria (41 of them from Vienna, Lower Austria, Burgenland). Around 54% of the headquarters’ purchasing revenue is generated near Vienna (less than 500 km away)

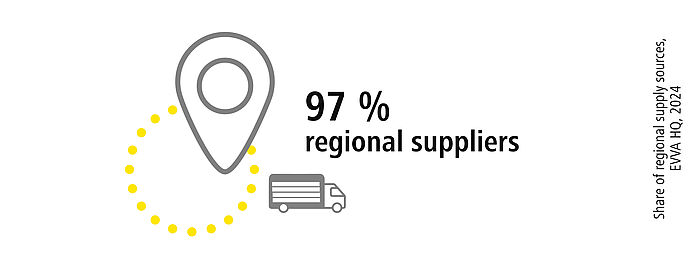

97% regional suppliers

Since virtually all materials and product components for the international EVVA Group are procured via the headquarters in Vienna, EVVA defines suppliers within a radius of 1,000 km of the headquarters as regional sources. The vast majority of our suppliers are based in this area. EVVA has been able to achieve its goal of increasing the share of regional supply sources from 93% to over 95% by 2024! In 2024, we are at 97% because EVVA is sourcing additional components from Europe and no longer from overseas.

We are talking about “regional” rather than “local” suppliers. There are two reasons for this definition: On the one hand, in the sense of a 'Europe of the Regions', with which the EU wishes to support regional autonomy. In terms of CO₂ emissions, a supplier from nearby Bratislava is no less regional than a supplier from the more distant Austrian Vorarlberg. On the other hand, many of EVVA’s essential material manufacturers, with whom we have had very close business relationships for decades, come from Central and Eastern Europe.

Very high proportion of regional EVVA suppliers

- EVVA purchases the vast majority of materials and components from European sources. And approx. 3% from Asian, such as key fobs, key tags or stainless steel parts for electronic handles

- Very stable and long-standing business relationships: EVVA has been connected to the main suppliers for decades, often over several generations. In figures: With 70% of the regional suppliers, EVVA has been working for at least 25 years of close business contact

Challenges

As the above list shows, EVVA cannot obtain all the parts required for production from regional sources. For certain product categories, there is practically no more regional competitive industry. The production of fittings for electronic access systems, for example, is labour-intensive and the purchase of raw materials is more expensive than that of finished products. In the early 2000s, the European fittings industry therefore moved to Asia, especially to China. But this also brought challenges, which resulted from different company cultures, ways of working, communication and distance. These challenges were exacerbated by the lack of transparency in supply chains. EVVA has therefore adopted a new approach to fittings:

Strengthening the fittings industry – from Asia back to Europe

Together with one of its European suppliers from the fittings industry (d line in Denmark), EVVA reconstructed a former fittings production facility in Lithuania in 2023. EVVA and d line were thus able to shorten response and delivery times, bring raw material processing back to Europe and ensure the quality standards in their own production. A further advantage is that the supply chains for this are more transparent and closer.

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?