Management approach – our why

In a production plant with numerous machines and tools, the safety of employees at work is a top priority. Especially employees in production and logistics are exposed to hazards that can endanger their health and security. This is why EVVA has defined “occupational safety and health protection” as a significant negative impact in its own business activities.

Concepts for occupational safety and health protection

(ESRS S1-1)

Corresponding concepts are planned, implemented and monitored at headquarters by the responsible security specialist and, if necessary, with the Human Resources Development department. Other affected locations – e.g. because they are also a production facility or exceed a certain legal operating size – are also implementing corresponding concepts. The area of application mainly concerns employees at the power plants in Vienna, Krefeld and Tišnov, who have a greater risk potential due to the mechanical equipment. Those responsible regularly report on the progress of sustainability goals to the Sustainability Board, which also includes the management.

- Occupational safety is anchored in the Code of Conduct for EVVA employees. More about this Code of Conduct and the EVVA Human Rights Policy under Responsible Corporate Governance

- Information on occupational safety can be viewed at any time on the intranet, at the works council and in neuralgic places in the building. Such as the checklist for emergencies, emergency numbers, fire behaviour, etc.

- EVVA has converted safety and health measures for employees into a health programme. More on this below under "Measures that prevent or mitigate the negative impacts

- The Quality and Process Management unit coordinates the ongoing risk analysis for the Vienna, Krefeld and Tišnov power plants as part of ISO 9001 certification. It also covers occupational safety

- All EVVA locations are located in the EU or Switzerland – in countries with high social and legal standards, including with regard to occupational safety and human rights. We respect all applicable social and ethical obligations and are guided by the principles of the Universal Declaration of Human Rights, the United Nations Global Compact, the OECD Guidelines for Multinational Enterprises and the International Labour Organisation’s (ILO) Declaration on Fundamental Principles and Rights at Work. Contact persons for questions or incidents in which rights may have been violated are the respective managers, works councils, management, the Legal Compliance department and confidential advisers

Involvement of our employees (ESRS S1-2)

Employees in production and logistics are vulnerable to the negative effects in terms of occupational safety. Your point of view is taken into account, for example, by means of employee surveys, which also deal with occupational safety and psychological stress, as well as by regular inspections with safety specialists. Measures have already been derived from this, such as more ergonomic chairs and floor renovations.

Employee orientation discussions and internal improvement initiatives also result in documented suggestions and concrete target agreements. Works agreements are jointly processed, concluded and signed by the Management Board and the Works Council (e.g. regarding the whistleblower tool, alcohol ban, etc.) in order to take the interests of the employees into account and incorporate them into agreements.

Procedures and information channels (ESRS S1-3)

The direct exchange between employees and managers and/or with employee representatives of EVVA is often the first dialogue to communicate problems and risks and lead to solutions. However, there are many other opportunities for employees to participate, report and check. Employee orientation discussions and improvement initiatives such as WoW! and EPOS, the Info breakfasts/cafés with management, the anonymous whistleblower tool, Welcome Lunches with management/HR as well as the regular Jour fixes of management/HR with works councils that bring up employee concerns. The participation formats are carried out on a regular basis, which enables continuous follow-up and monitoring of the topics raised.

The occupational safety processes at EVVA are subject to strict safety requirements and are regularly reviewed.

Comprehensive measures for the protection and health of our employees (ESRS S1-4)

The following list includes important measures taken and implemented during the reporting year to prevent or mitigate the negative impact on the company’s own workforce in terms of occupational health and safety. All measures contribute to an expected result: keep the number of work-related accidents to a minimum.

1 Health promotion:

- EVVA promotes participation in running events, such as the international Wings for Life Run or the Vienna City Marathon every year. The company pays the start fees and provides the T-shirts. EVVA Vienna financially supported the participation of 97 employees in 4 running events in 2024

- EVVA covers a large proportion of the meal costs in the company’s own canteen at the headquarters. All employees can choose from three different freshly cooked menus every day at lunchtime, including vegetarian and vegan menus. A daily breakfast offer at reduced prices will also be provided

- In recent years, numerous health lectures by specialists have taken place directly in the company, e.g. on women’s/men’s health, tips on smoking cessation, dealing with migraines, etc. In 2024, the headquarters offered free screenings and lung function tests for employees. The test allows early detection of constrictive lung diseases such as COPD or pulmonary fibrosis

- Every year EVVA distributes apple bags to employees for a “healthy start to autumn”

- Free flu vaccination; EVVA will pay the vaccination fee for the tick/FSME vaccination. The company doctor offers the vaccination directly at the headquarters

- Germany has introduced the “moving break”: Physiotherapists visit employees once a week and perform stretching and relaxation exercises

2) Occupational health and safety:

Unless otherwise mentioned, most programmes relate to the headquarters, which is by far the largest production site of the EVVA Group. The other two power plants (Krefeld, Tišnov) and other locations also have safety specialists, occupational physicians, fire protection officers, etc., depending on their size. to the side.

At headquarters, the following representatives are jointly responsible for occupational safety and risk analysis or are ready to intervene in an emergency:

At headquarters, the following representatives are jointly responsible for occupational safety and risk analysis or are ready to intervene in an emergency:

> 1 safety specialist

> 4 security officers

> 1 company doctor

> 3 fire protection officers

and > 16 fire protection officers

> 41 first aiders for first aid

> 2 Elevator control room

> 1 poison officer

> 2 representatives for environment/disposal/

Consumables

> 1 Dangerous Goods Officer (external)

- Once a year, the headquarters and the two other power plants in the ASA (Occupational Health and Safety Committee) discuss current topics and laws and how these can be implemented optimally in the company. The participants are safety specialists, occupational physicians, fire protection officers, works council and management

- The EPOS initiative (EVVA Production System) bundles all optimisation projects in production - including occupational safety, workplace cleanliness and environmental protection. In 2024, EVVA expanded the internationally renowned 5S measure for efficient work design to “6S” with the point of “Working safely”. Employees can also point out and report hazards themselves at any time, regardless of the EPOS rounds: to their manager, to the safety professionals, via the ASA, to the works council or directly to the management

- Workplace inspections and SOSU tours (SOSU stands for security, order, cleanliness, environmental protection). In these internal, unannounced audits, EVVA checks compliance with security, environmental protection and lean management standards. Is the PPE always in use, does it need to be replaced? Are all protective devices still intact? Are there trip hazards? Deviations are documented and targets checked

- Comprehensive safety precautions for electroplating (only available at headquarters):

> Another specialist is always present when preparing the chemicals and filling the electroplating tanks to prevent incorrect application or mix-up. This person also checks whether the person performing the work puts on each and every piece of protective equipment – such as gloves, mask and apron

> Preparations must not be completed shortly before the end of the day, as this can lead to work that is prone to errors quickly

> Additional regular training and emergency drills

> The chemicals for the cleaning bath have been changed from solid (powder) to liquid; which remain fixed for the nickel bath. The reason: it makes it even less likely they will be mixed up. A liquid supply can also be easily automated

> Step-by-step instructions via a digital worker assistant with monitor and integrated scale for dosing. Every step – including donning PPE – must be confirmed before the next one can be implemented

- Company healthcare. Once a week, the EVVA company doctor at headquarters provides information on medical issues (such as illnesses, flu, ergonomics, etc.), measures blood pressure, takes vaccinations, issues prescriptions and referrals for specialists. Company doctors also work at the German sites in Krefeld and Leipzig

- Ergonomically designed work islands in assembly (e.g. all work equipment within optimal reach, height-adjustable tables and chairs, ergonomically designed screwdrivers, etc.). The digital ergonomics module collects and documents loads in the work area - and derives suggestions for improvements to the workplace design. It was developed by EVVA in cooperation with the Fraunhofer Institute

Personal protective equipment at all locations, e.g. special gloves that help prevent cuts. Shoes with antistatic soles are used in electronics production. They protect employees and electronic components from electrostatic charges. At the same time, access control is installed in this zone to prevent walking without these shoes

Personal protective equipment at all locations, e.g. special gloves that help prevent cuts. Shoes with antistatic soles are used in electronics production. They protect employees and electronic components from electrostatic charges. At the same time, access control is installed in this zone to prevent walking without these shoes

- At the headquarters, floor rollers (photo on the right) are required for warehouse logistics. They are easy to use and replace the previously used transport skids. A significant long-term ergonomic benefit considering their intense, daily use.

- Defibrillators at different places in the building, which can also be used immediately and easily by laypersons in emergencies

3) Operational integration management OIM:

- At EVVA Germany, employees can make use of the legally prescribed "Business Integration Management" (BEM) after a long period of illness. The objective of the BEM is to keep employees healthy. With this offer, EVVA supports employees in the recovery process and in returning to everyday work. EVVA works with TÜV Rheinland, which provides neutral and competent specialists and advises on health and social security issues, among other things. OIM is a voluntary offer to employees

4) Training:

- The EVVA Academy integrates health-related topics into the “Living Leadership” training course for managers. For example, it emphasises the importance of mindfulness and balance and their positive health effects. Employees at all locations have access to many courses and videos on health on the EVVA digital learning platform “Masterplan”, which can also be viewed privately

- The safety professionals carry out all occupational safety training internally and are the first point of contact if problems or incidents arise here. EVVA is planning its own master plan learning path for occupational safety

- In employee surveys, EVVA collects the legally prescribed “Evaluation of psychological stress at the workplace”

Effectiveness of the measures

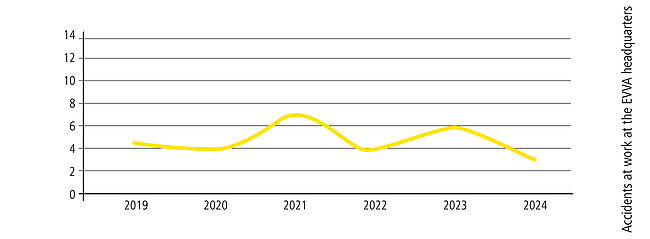

One factor to check the effectiveness of the measures is the statistics of “work accidents” and “accident-free days”. EVVA sets corresponding targets (described below) that are measured against them. The number of employees participating in running events, health services and canteen visits remains constant throughout the years and demonstrates the acceptance of these measures. All new employees at headquarters receive mandatory occupational safety training upon joining the company, and employees in production also receive this training annually.

Safety specialists/occupational doctors conduct regular inspections and assess workplaces and occupational safety individually. The frequency and type of work-related accidents are documented, and current focus measures are defined based on these, such as the topic of eye protection and the consistent use of protective goggles.

Number of occupational accidents (ESRS S1-14)

In 2024, there were three reportable occupational accidents in Vienna and four in Krefeld.

Reporting requirements for occupational accidents are those from three days of sick leave/lost time. Serious work-related accidents are very rare at EVVA; they usually involve minor injuries such as cuts or bruises. There were no work-related deaths, even in the reporting year. Travel accidents are not included in the following statistics. All EVVA employees are covered by legal requirements and/or their own health and security programs.

| EVVA location | Number of reportable occupational accidents in 2024 |

|---|---|

| Vienna | 3 |

| Krefeld | 4 |

| Tišnov | 0 |

| Prague | 0 |

| Leipzig | 0 |

| Warsaw | 0 |

| Nitra | 0 |

| Villorba | 0 |

| Rotkreuz | 0 |

| Hengelo | 0 |

| Buizingen | 0 |

| Stockholm | 0 |

Number of occupational accidents at EVVA headquarters:

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?