Our recycling strategy

Using raw materials sparingly and reusing them as well as possible is a central part of our environmental policy. We focus on the use of secondary materials and recycle various raw materials, such as:

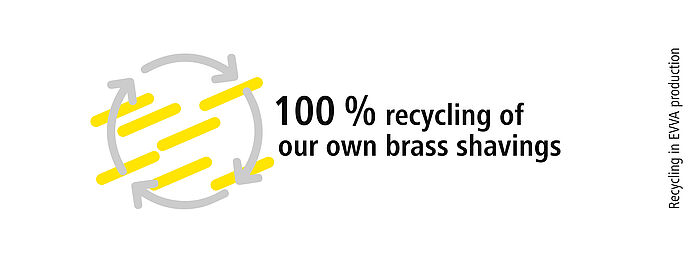

Own metal shavings

Brass is the most important metal for EVVA production. 100% of the brass chips generated in EVVA’s production are already melted and recycled. This accounts for about one third of the current recycled content of 90%. The other two thirds come from the scrap trade (copper cables, etc.) of the suppliers. This means that EVVA is already hardly dependent on primary raw materials for its most important production material. Together with our suppliers, we are trying to increase this high value even further – see the target description under Circular Economy Overview.

EVVA relies on “machining technology” for complex product parts, which separates excess material in the form of chips and thus enables high recycling rates. This also brings a qualitative advantage: The materials are becoming increasingly homogeneous in their chemical structure thanks to the recycling processes and are therefore easier to process by production machines. Recycling therefore also increases material quality.

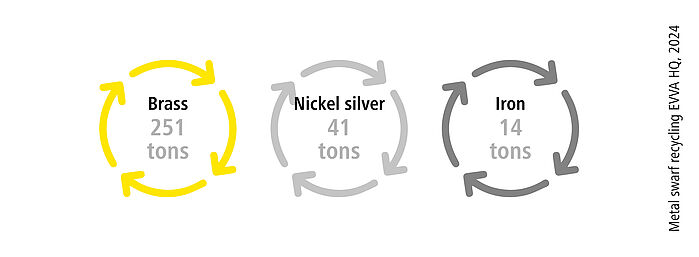

Metal recycling (chips and solid waste) per year

Internal packaging/reusable pallets

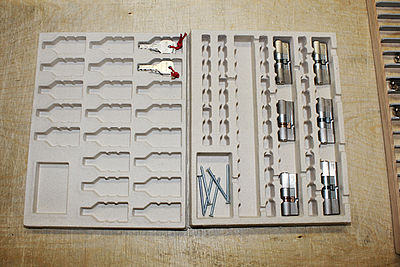

In recent reporting years, EVVA was able to increase its share of internal packaging, which is usually our reusable pallets (see photo), to 25% and reduce the share of sales packaging to 75%. This change in ratios means that EVVA can reuse more packaging. This is because EVVA transports the half-parts (i.e. cylinder housings, cores) via the reusable pallet system to its own subsidiaries and also to some external sales partners. This eliminates the need for any additional packaging. The advantages of EVVA reusable pallets extend across all sustainability categories:

In recent reporting years, EVVA was able to increase its share of internal packaging, which is usually our reusable pallets (see photo), to 25% and reduce the share of sales packaging to 75%. This change in ratios means that EVVA can reuse more packaging. This is because EVVA transports the half-parts (i.e. cylinder housings, cores) via the reusable pallet system to its own subsidiaries and also to some external sales partners. This eliminates the need for any additional packaging. The advantages of EVVA reusable pallets extend across all sustainability categories:

- Economy: Transport is cheaper and safer (no scratch damage as is possible with metal pallets). The production robots can pick the workpiece directly from the reusable pallets, which was not possible with the conventional containers

- Environment: Since 2015, EVVA has increased the share of its reusable pallets in the total internal packaging volume from 40% to 85%

- Employees/social: Traditional metal containers weigh approximately 30 kg when filled. Our reusable pallets weigh only 9 kg – making them easy to transport without the risk of injury

Sales packaging

As mentioned, they currently make up 75% of all EVVA packaging. Since 2017, EVVA has been using product packaging in sales that is made of 100% environmentally friendly, recyclable cardboard and not plastic/polystyrene. Only overpacks (for protection during transport) are still made of synthetic material/plastic.

As mentioned, they currently make up 75% of all EVVA packaging. Since 2017, EVVA has been using product packaging in sales that is made of 100% environmentally friendly, recyclable cardboard and not plastic/polystyrene. Only overpacks (for protection during transport) are still made of synthetic material/plastic.

Additional benefits:

- Waste paper containers are everywhere. No special disposal locations are necessary

- Low storage costs, because the basic package is always the same. The product is identified by means of attractively designed label and sleeve

- The packages stack well and save space

- Cardboard produces less and less CO2 during production (e.g. compared to polystyrene). The processes for this have become even more environmentally friendly in recent years

In total, EVVA reuses around 35% of the total packaging volume (this includes internal packaging as well as sales packaging for all product categories).

Paper

In 2024, 4,372 kg of paper was generated at the headquarters, which is collected and recycled by the magistrate. Our paper consumption is to be reduced – see target description under Circular economy Overview. By switching to digital processes (e.g. for design drawings, order documents, orders, invoices via PDF, etc.), EVVA has already been able to save several tonnes of paper in recent years.

- Order managment in Vienna, Krefeld and Hengelo has only processed orders digitally since 2022. This saves around 200,000 sheets of A4 paper per year at the headquarters, 100,000 sheets at the sites in Krefeld and 20,000 sheets in Hengelo. 200,000 sheets mean approx. 1.5 tonnes less CO2 (source calculations: www.ezeep.com/de/co2-neutral-drucken/)

- Invoicing: EVVA has automated the incoming invoice process at headquarters. Approx. 98% of invoices arrive at us paperless. Only approx. 2% are still processed in paper form, as electronic transmission is not possible for the affected suppliers

All target descriptions relating to recycling & resources can be found under Circular Economy Overview.

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?