When and what do you buy at the best price on the world market? This is the question that every manufacturing company asks itself. The issue becomes particularly important in times of crisis, pandemics or wars. EVVA reacted quickly at the start of the Ukraine war and was able to increase the purchasing volumes for main materials as a precautionary measure in order to optimise security of supply.

Fixed price variants have also been agreed with the energy provider for electricity and gas prices in order to diversify the risk and hedge against future sharp price jumps. After all, energy is a higher cost factor than in previous years.

Trend towards independence

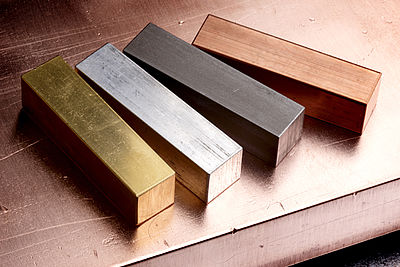

In the past, higher stock levels were still perceived as too expensive a solution, but this view has become relative due to the coronavirus and Ukraine situation. More flexible warehousing now serves as a precautionary measure to be better prepared for supply fluctuations and to be able to keep your own production running longer. For companies, greater security of supply means greater economic sustainability. EVVA has a high level of vertical integration, i.e. we can manufacture many small parts ourselves.

In the past, higher stock levels were still perceived as too expensive a solution, but this view has become relative due to the coronavirus and Ukraine situation. More flexible warehousing now serves as a precautionary measure to be better prepared for supply fluctuations and to be able to keep your own production running longer. For companies, greater security of supply means greater economic sustainability. EVVA has a high level of vertical integration, i.e. we can manufacture many small parts ourselves.

Single-source analyses

Where supplier dependencies have previously occurred in isolated cases, EVVA has carried out single-source analyses in order to be able to select at least two suppliers. At the same time, EVVA maintains its stocks of critical product parts by making early purchases.

EVVA has also analysed missing material: Where and why do material bottlenecks occur (e.g. due to spontaneous urgent large orders or unreliable supply sources) and how can they be avoided? These learning processes help EVVA to optimise the Kanban system, adapt the working time models to large orders and maintain delivery performance, among other things.

The major EVVA advantage:

In-house machine and tool construction

EVVA can repair the necessary production machines and tools itself and often design them in-house. A large part of the EVVA machine fleet was planned and implemented by our in-house mechanical engineering department - which has a positive effect on independent maintenance and delivery capability.

EVVA can repair the necessary production machines and tools itself and often design them in-house. A large part of the EVVA machine fleet was planned and implemented by our in-house mechanical engineering department - which has a positive effect on independent maintenance and delivery capability.

This competence and the traditionally high level of manufacturing depth bring advantages that many competitors do not have. EVVA is able to manufacture countless access system variants and order sizes itself - up to lot size 1, i.e. only one customised security product.

We have been training our apprentices in mechanical engineering and toolmaking for decades, so that the know-how for our own machine innovations remains in-house. An independence that strengthens our economic sustainability.

AT

AT

DE

DE

DE

DE

UK

UK

INT

INT

How would you like to share?